In this post Standard Operating Procedure of Issuance of consumable item through requisition cum issue slip in Pharmaceuticals is describe.

1.0 OBJECTIVE:

1.1 To lay down the procedure for issuance of consumable item through requisition cum issuance slip.

2.0 SCOPE:

2.1 This procedure is applicable to issuance of consumable item through requisition cum issuance slip.

3.0 RESPONSIBILITY:

3.1 Officer and Executive : Issuance of consumable item through requisition cum issue slip

3.2 Officer and Executive IPQA : SOP Compliance

3.3 Head Production : SOP Compliance

4.0 DEFINITION(S):

4.1 NA

5.0 PROCEDURE:

5.1 Safety Precautions

5.1.1 Use proper safety apparel such as secondary gowns, rubber hand gloves and safety goggles during IPA dispensing.

5.2 The following material issue through requisition cum issuance slips.

5.2.1 Few solvents such as IPA required for area, machine or equipment cleaning.

5.2.2 Some lubricant such as talcum require during coding.

5.2.3 Starch for cleaning of new equipment.

5.2.4 Sodium lauryl sulfate for cleaning of SS Bin / IPC through Bin washing and Drying machine.

5.2.5 Fill up the Requisition cum issue slip and give remark as per Annexure-I.

5.2.6 Get the signature of requisitioned by and approved by Department Head on the Requisition cum issue slip.

5.2.7 For receipt of talcum, IPA and other solvents for area, machine or equipment cleaning; the details of Product, Batch number and Batch size are not required.

5.2.8 Store personnel shall issue required material as per respective SOP of warehouse.

5.2.9 Receive the material and check it’s weight. Sign against “Checked By” column of the Requisition cum issue slip.

6.0 ABBREVIATION(S):

6.1 IPA : Iso-Propyl Alcohol

6.2 SOP : Standard Operating Procedure

7.0 REFERENCE(S):

7.1 NA

8.0 ANNEXURE(S):

9.0 DISTRIBUTION:

9.1 Master copy : Quality Assurance

9.2 Controlled copy( s) : Production department (01), Quality Assurance(01)

9.3 Reference copy (s) : Production department(02)

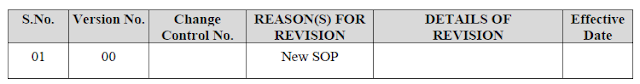

10.0 REVISION HISTORY:

ANNEXURE I

REQUISTION CUM ISSUE SLIP

.webp)

%20Web%20of%20pharma%20.webp)