In this post Standard Operating Procedure Cleaning of Production Area in Pharmaceuticals is describe.

1.0 OBJECTIVE:

To lay down a procedure for the Cleaning of Production Area.

2.0 SCOPE:

The procedure is applicable to the Cleaning of Production Area.

3.0 RESPONSIBILITY:

Technical associate Production / House keeping personnel: Cleaning Officer and Executive : Supervision

Head Production : SOP compliance

IPQA Person : SOP compliance

4.0 DEFINITION(S):

NA

5.0 PROCEDURE:

5.1 Ceiling/ AHU grill /Dust collector pipe:

5.1.1 General precaution: Remove product from area.

5.1.2 Frequency: Once in a week or product change over whichever is earlier.

5.1.3 Climb on a ladder to clean the ceiling.

5.1.4 Wipe out the entire ceiling surfaces with dry lint free cloth followed by wet cloth dipped in purified water. Wipe out again with a dry lint free cloth.

5.1.5 Wipe the grill thoroughly from the outside with wet lint free cloth dipped in purified water, then wipe again with a dry lint free cloth.

5.1.6 Wipe the outer side of dust collector pipe along with the pendant, which cannot dismantle, clean the internal surface by using a dry lint free cloth followed by wet and again followed by dry lint free cloth.

5.1.7 Dismantle the dust collector pipe, butterfly valve, put it in to a virgin polybag, and transfer it to the respective wash area.

5.1.8 Unscrew the bottom SS cap of the pendant and remove the adhering powder if any.

5.1.9 Clean the dismantle part of the dust collector pipe in the respective wash area with purified water using nylon scrubber during product changeover or same product run for a week in respective area.

5.1.10 Dry the clean dismantled part of the dust collector pipe by using compressed air.

5.1.11 Reassemble the dried part of the dust collector and fix on the respective place.

5.1.12 Use a safety goggles to prevent dust falling into the eyes.

5.2 Walls / electrical fixtures /windows / doors:

5.2.1 Frequency: Once in a week or product change over whichever is earlier.

5.2.2 Wipe the wall surface with a wet cloth dipped in water to remove all adhering material.

5.2.3 Wipe out entire wall surface thoroughly with a dry lint free cloth

5.2.4 Remove dust from panel frames, electrical switch, glass frame and switchboard with a clean dry cloth.

5.2.5 Wipe the entire glass panels, windows, and doors with a cloth dipped in water.

5.2.6 Sprinkle few drops of cleaning agent over windows and doors. Wipe it out with a clean and dry lint free cloth.

5.2.7 Wipe the door closure thoroughly with a cloth to remove adhering material.

5.2.8 Wipe all the tables with lint free cloth dipped with purified water once in week or whenever is required.

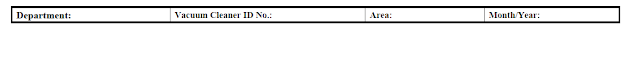

5.3 Floor: Clean the floor with the help of vacuum cleaner of the respective area or by dust collector. After completion of cleaning of area, clean the vacuum Cleaner as per SOP and clean the dust collector pipe.

5.3.1 Cleaned by scrubber machine:

5.3.1.1 Frequency: Minimum once in shift or batch/product change over.

5.3.1.2 Prepare 0.1% teepol solution as per the scrubber machine capacity.

5.3.1.3 Clean the entire floor by using a scrubber machine.

5.3.1.4 Remove the above cleaning solution from the scrubber machine into the drainage of the washing area. Clean the scrubber machine.

5.3.1.5 Fill purified water in scrubber machine and clean the entire floor by using a scrubber machine.

5.3.1.6 Drain the purified water used/unused from scrubber machine in to drainage of washing area and clean the machine.

5.3.1.7 Fill 2.5% v/v Savlon / Dettol (freshly prepared) in scrubber machine as per enclosed area cleaning and sanitization checklist and disinfect the entire floor

5.3.1.8 Drain the used/unused disinfectant solution from the scrubber machine into the drainage of the Janitor room.

5.3.1.9 Clean the scrubber machine as per the standard operating procedure and keep it in the washing area.

5.3.1.10 Ensure that the pallets are moved aside so as to facilitate the proper cleaning of the floor beneath.

5.3.2 Manual cleaning and sanitization:

5.3.2.1 Frequency: Minimum once in shift or batch/product change over

5.3.2.2 Prepare 0.1% teepol solution in SS bucket.

.webp)