In this post Standard Operating Procedure Cleaning and Operation of Pack i 2 Camera Inspection System for Online Pharmacode Scanning of Carton and Leaflet in Pharmaceuticals is describe.

1.0 OBJECTIVE:

To lay down a procedure for cleaning & operation of PACKi 2 Camera Inspection System for online Pharmacode scanning of Carton and Leaflets.

2.0 SCOPE:

This procedure is applicable for Cleaning & Operation of PACKi 2 Camera Inspection System in Production Department.

3.0 RESPONSIBILITY:

Technical Assistant: For cleaning & operation.

Production Supervisor: Supervision of cleaning and operation. IPQA: Line Clearance and SOP compliance.

Production Head: SOP compliance.

4.0 DEFINITION (S):

NA

5.0 PROCEDURE:

5.1 CLEANING:

5.1.1 Ensure that all the materials of previous batch are removed from the packing line.

5.1.2 Remove “UNDER PROCESS” label and affix “TO BE CLEANED” label on the machine with date and sign of the production officer.

5.1.3 Switch ‘‘OFF’’ the utility supply before cleaning.

5.1.4 Clean the control panel with clean and dry lint free cloth.

5.1.5 Clean the top and outer surface of machine with the dry lint free cloth.

5.1.6 Replace the “TO BE CLEANED” status label by “CLEANED” status label on the machine with date and sign of the production officer.

5.1.7 Clean the area as per SOP.

5.2 OPERATING PROCEDURE

5.2.1 Switch ‘‘ON’’ the mains; switch on UPS wait for 5 sec., switch on console unit by pressing ‘Red’ switch on the RIGHT SIDE wall of the console unit.

5.2.2 Pack i screen will be displayed and asking for login names & password. On selecting correct user name & password followed by OK, system will display. “DO YOU WANT TO SET THE CAMERA? Press ‘‘NO’’. Then system will go in learn mode.

5.2.3 Pass the object in front of camera to grasp the image.

5.2.4 Screen will display “PLEASE SET IMAGE & PRESS OK BUTTON” If image is ok then press ‘‘OK’’.

5.2.5 The screen will display “Please give area for reference’. Then give AREA (ROI) & PRESS “OK” BUTTON

5.3 SETTING OF PHARMA CODE READER FOR CARTON AND LEAFLET:

5.3.1 Pharma code setting for carton (Camera setting 1):

5.3.1.1 Ensure that “PACKi2CAM" pharmacode check system is cleaned.

5.3.1.2 Get the line clearance by Quality Assurance.

5.3.1.3 Switch ON the mains. Switch ON the console unit by pressing on the RIGHT SIDE wall of the console unit. Check “MCB” left side wall of the console unit.

5.3.1.4 “PACKi2CAM” screen will be displayed asking for login name and password.

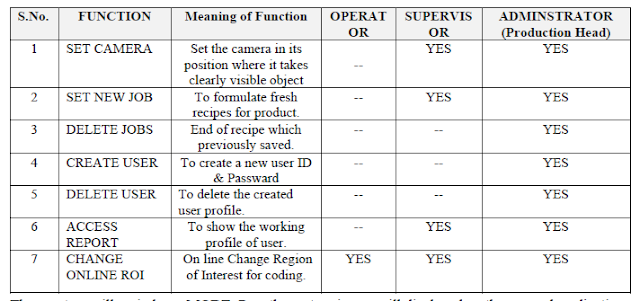

5.3.1.5 Following tables given below according to user rights.

5.3.1.6 Then system will go in learn MODE. Pass the carton; image will displayed on the screen by adjusting label gap sensor image position (horizontal can be adjusted).

5.3.1.7 To start fresh job it will display learn mode as waiting for carton.

5.3.1.8 Pass the carton through the camera. Check the camera, flash, trigger position, adjust proper light, no wrinkle.

5.3.1.9 Then screen will display “PLEASE SET IMAGE AND PRESS OK BUTTON” if image is ok then press ‘‘OK’’.

5.3.1.10 The screen will display “Please give the area of reference”. Then give AREA (ROI) & press OK button.

5.3.1.11 In option window click on Pharmacode option: green indicator of Pharmacode will glow. Pop up window will be displayed.

5.3.1.12 Pharmacode value directly feed it or else to find value click on the bar code indicator. Choose thin and bar as seen in the image so that same combination of bar is produced. It will give Pharmacode value in value indicator. Click direction arrow, value will change. Select ppropriate

direction and click OK and press ‘CLOSE’ to return main screen.

5.3.1.13 Give ROI on Pharmacode. In right centre in preview window image of Pharmacode will be displayed.

5.3.1.14 Press test button to check the Pharmacode value if Pharmacode value is wrong then it shows “Pharma value is hard to analyze’’. Give proper ROI or press direct button”. If pharma value is scanned

successfully. Than it shows “Pharma value is scanned successfully”. Press OK button to exit Pharma setting.

5.3.1.15 For ejector system of cam 1, product must be have zero value.

5.3.1.16 ENTERING JOB NAME:

5.3.1.16.1 Click on text box ‘JOB NAME’. Keypad will appear ENTER job name with the help of keypad. If job name already exist system will ask for re-entering the job name. After click OK keypad will appear again. Enter new job name and press OK to return main menu.

5.3.1.17 LOAD FROM PREVIOUS JOB:

5.3.1.17.1 Click load button and give job name and click OK button to return main screen. Press start button to run the job.

5.3.2 Pharmacode setting for Leaflet (Camera 2):

5.3.2.1 In option window click on the Pharmacode option; green indicator of Pharmacode will glow. Pop up window will be displayed.

5.3.2.2 Set the Pharmacode same as Cam 1 as per point 5.3.1.

5.4 CHALLENGE TEST FOR PHARMACODE READER:

5.4.1 CHALLENGE TEST FOR CARTON:

5.4.1.1 After setting of Pharmacode reader, Production and IPQA supervisior shall take four good carton of product.

5.4.1.2 Pass these carton through machine, all good carton must be pass.

5.4.1.3 Now mark one or two extra lines in Pharmacode of one carton.

5.4.1.4 Pass this carton with extra line through machine.

5.4.1.5 The machine must reject the carton by ejector mechanism into rejection box.

5.4.1.6 Challenge test shall be performed at start, after every four hour of operation, at the end of operation and after any maintenance.

5.4.1.7 Record the challenge test result in attached ANNEXURE-I.

5.4.2 CHALLENGE TEST FOR LEAFLET:

5.4.2.1 After setting of pharmacode reader, production and IPQA supervisor shall take four good leaflet of product.

5.4.2.2 Pass these leaflets through machine, all good leaflets must be pass.

5.4.2.3 Now mark one or two extra lines in the pharmacode of one leaflet.

5.4.2.4 Pass this leaflets through machine.

5.4.2.5 The machine must reject the leaflet by ejector mechanism into rejection box.

5.4.2.6 Challenge test shall be performed at start, after every four hours of operation, at the end of operation and after any maintenance.

5.4.2.7 Record the challenge test result in attached ANNEXURE-I.

6.0 ABBREVIATION (S):

SOP: Standard Operating Procedure ROI: Region of interest

7.0 REFERENCES (S):

SOP: Cleaning of production area.

8.0 ANNEXURE (S):

Annexure I (CAMERA CHALLENGE TEST RECORD)

9.0 DISTRIBUTION:

9.1 Master Copy : Quality Assurance

9.2 Controlled copy (S) : Production department, Quality Assurance

9.3 Reference copy (S) : Production department

ANNEXURE I

CHALLENGE TEST FOR ONLINE PHARMACODE SCANNING OF CARTON

.webp)