In this post Standard Operating Procedure Cleaning and Operation of De-blistering Machine in Pharmaceuticals is describe.

1.0 OBJECTIVE:

1.1 To lay down a procedure for Cleaning and Operation of De-blistering machine.

2.0 SCOPE:

2.1 This SOP is applicable for Cleaning and Operation of De-blistering machine in Production Department.

3.0 RESPONSIBILITY:

Technical Associate : Operation and cleaning of equipment

Officer/ Executive Production : Execution of activity

Head Production : SOP Compliance

IPQA : Line Clearance of area and equipment.

4.0 DEFINITION (S):

4.1 NA

5.0 PROCEDURE:

5.1 “Type A” CLEANING:

This is a cleaning procedure for changeover of one batch to next batch of same product.

5.1.1 Replace the ‘‘EQUIPMENT STATUS’’ label and affix dully filled “UNDER CLEANING” status label on equipment with date and signature of the production officer as per SOP (Status labeling).Record the cleaning start time in equipment usage log as per SOP (Making entries in equipment usage &

5.1.2 cleaning log sheet).

5.1.3 Ensure that the De-blistering Machine is switched OFF.

5.1.4 Dismantle the tablet collection tray & tablet discharge chute from the machine.

5.1.5 Clean the tablet collection try, tablet discharge chute with the lint free cloth.

5.1.6 Clean the machine body with lint free cloth.

5.1.7 Fix the dismantled parts to the de-blistering machine.

5.1.8 Record the cleaning activity in the equipment usage log as per SOP (Making entries in equipment usage & cleaning log sheet).

5.2 “Type B” CLEANING:

5.2.1 Replace the ‘‘EQUIPMENT STATUS’’ label and affix dully filled “TO BE CLEANED” status label on equipment with date and signature of the production officer as per SOP (Status labeling).Record the cleaning start time in equipment usage log as per SOP (Making entries in equipment usage &

5.2.2 cleaning log sheet).

Ensure that the De-blistering Machine is switched OFF.

5.2.3 De-dust the machine with dry lint free duster and dismantle the tablet collection tray, tablet discharge chute. Affix dully filled “TO BE CLEANED” status label on parts with date and signature of the production

5.2.4 officer as per SOP (Status labeling) and transfer to washing area in virgin polybag.

5.2.5 Flush the dismantled parts with purified water sufficient to remove the powder. To remove the adhered particulate scrub the parts with nylon brush using purified water.

NOTE: 2% Sodium Lauryl Sulphate (SLS) solution shall be used for cleaning by scrubbing with nylon brush if API is Efavirenz before final rinsing of equipment/parts.

5.2.6 Finally rinse the dismantled parts with 10-15 liters water.

5.2.7 Dry the dismantled parts using a lint free duster and transfer to concern area in virgin polybag.

5.2.8 Finally clean the surface of the machine with wet lint free duster and followed by dry lint free duster.

5.2.10 Fix the dismantled parts to the de-blistering Machine.

5.2.11 Replace “UNDER CLEANING” status label with “CLEANED’ label.

5.2.12 Record the cleaning activity in equipment usage log as per SOP.

NOTE: The cleaned equipment is idle for 72 hours, after this period Wipe all the parts of equipment with 70% v/v IPA solution before use. It should be a counter sign on previous “CLEANED” label by production & QA officer with date as per SOP.

5.3 OPERATING PROCEDURE:

5.3.1 Equipment setting:

5.3.1.1 Switch ‘OFF’ the main from electric panel.

5.3.1.2 Remove the lower guard from pack entry side for access to support wheels.

5.3.1.3 Relieve the pressure between the support wheels and knurled roller by revolving the external adjusting segment.

5.3.1.4 Loose clamp screw of blister guides and adjust them to suit the pockets. Ensure that the center support wheel is exactly between the two rows of blister.

5.3.1.5 Loosen the side support wheels and adjust to coincide with the blister guides. For packs with minimal sealing margin, the side support rollers can be set 1mm with in the blister guides to

ensure proper grip.

5.3.1.6 Set the nip between top knurled roller and bottom support wheels such that the top knurled roller will only rotate when the pack is inserted.

5.3.1.7 Set the wheel spacing visually by inserting a pack in the blister guides rotate the motor by hand and observe the removal of tablet.

5.3.2 Operation:

5.3.2.1 After the line clearance from QA, put the ‘EQUIPMENT STATUS’ label on the machine.

5.3.2.2 Open the Rejection Box and take rejected blisters for De-blistering.

5.3.2.3 Switch ‘ON’ the main from electric panel and start the De-blistering as per requirement and record the start time of De-blistering in respective BPR / Document.

5.3.2.4 Blister packs are fed into the machine manually through blister guides and are taken up by the wheels and knurled roller.

5.3.2.5 The wheels are required to run between adjacent rows of product and offer support to the pack as the knurled roller expels the product from the pack.

5.3.2.6 The pressure between the wheels and roller, the packs are firmly held during the operation.

5.3.2.7 The expelled product will fall in to the tray.

5.3.2.8 Inspect all De-blistered tablets on inspection table manually for any rejection of tablets.

Note: All the inspected tablets to be repacked at the end of the batch in last shipper / shippers. Online rejection of blisters if any will be destroyed. Reference SOP (Movement of materials from one stage to another).

5.3.2.9 Switch ‘‘OFF’’ the main from electric panel.

5.3.2.10 Affix ‘TO BE CLEANED’ label on the machine after completion of batch.

6.0 ABBREVIATION (S):

6.1 IPA : Iso Propyl Alcohol

6.2 V/V : Volume / Volume

6.3 Q.A. : Quality Assurance

6.4 SOP : Standard Operating Procedure

6.5 % : Percentage

6.6 mm : Millimeter

6.7 SLS : Sodium Lauryl Sulphate.

7.0 REFERENCE(S):

7.1 SOP No.: Movement of Materials from one Stage to another.

7.2 SOP No.: Making Entries in Equipment Usage and Cleaning Log Sheet.

7.3 SOP No.: Status Labeling

8.0 ANNEXURE(S):

9.0 DISTRIBUTION:

9.1 Master Copy : Quality Assurance

9.2 Controlled copy (s): Production Department (01 Copy), Quality Assurance (01 Copy)

9.3 Reference copy (s) : Production Department (06 Copies)

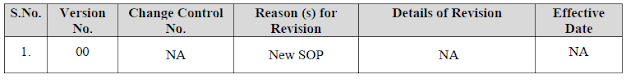

10.0 REVISION HISTORY:

.webp)