In this post Standard Operating Procedure Cleaning and Operation of Checkweigher (Model: MT-S, Make: Metler Toledo) in Pharmaceuticals is describe.

1.0 OBJECTIVE:

To lay down the procedure for the Cleaning and Operation of Checkweigher.

2.0 SCOPE:

This procedure is applicable to the Cleaning and Operation of Checkweigher in Production Department.

3.0 RESPONSIBILITY:

Technical Associate: Operation

Officer/ Executive Production: Supervision

IPQA: SOP Compliance

Head Production: SOP Compliance

4.0 DEFINITION (S):

NA

5.0 PROCEDURE:

5.1 CLEANING

5.1.1 Affix dully filled “TO BE CLEANED” status label on equipment with date and Signature of the Production Officer as per SOP.

5.1.2 Enter the cleaning starting time in equipment usage log sheet as per SOP.

5.1.3 Ensure that the main power supply is switched ‘OFF’.

5.1.4 Ensure that no cartons of previous product are lying in and around the checkweigher.

5.1.5 Clean the conveyer belts of checkweigher by using dry lint free cloth.

5.1.6 Clean the rejection box with the dry lint free cloth.

5.1.7 Clean the entire surface of the machine with clean and dry lint free cloth.

5.1.8 Open the guards of the machine.

5.1.9 Clean the guards with clean and dry lint free cloth.

5.1.10 Clean the area inside the guard with clean and dry lint free cloth.

5.1.11 Remove the Conveyer belts of Checkweigher and clean it with moist cloth and then dry with clean lint free cloth.

5.1.12 Open the control panel of Checkweigher, clean the area with the dry cloth.

5.1.13 Clean the rejection box with the dry lint free cloth.

5.1.14 Clean the entire surface of the machine with clean and dry lint free cloth.

5.1.15 Wipe the machine surface and panel with 70% v/v IPA solution.

5.1.16 Affix label on checkweigher as ‘CLEANED’ with date and signature of the Production Officer. Record the cleaning activity of Checkweigher in equipment usage log as per SOP.

5.1.18 The cleaned equipment is idle for 72 hours, after this period Wipe all the parts of equipment with 70% v/v IPA solution before use. And should be a counter sign on previous “CLEANED” label by production & QA officer with date as per SOP.

5.1.19 Record the cleaning activity of Checkweigher in equipment usage log as per SOP.

5.2 Recipe Preparation:

5.2.1 Open the compressed air valve and ensure that the compressed air pressure should not be less than 3 kg/cm².

5.2.2 Switch ‘ON’ the mains of the machine.

5.2.3 Following screen shall be opened

5.2.4 Select the ‘menu’ option from the above window and following window shall be opened:

5.2.5 Select the ‘login’ option from the above window:

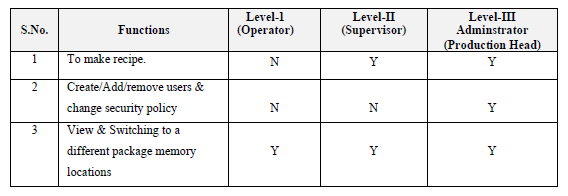

5.2.6 There are three ‘user’ with their rights assignments as given:

5.2.7 Then select user name and enter the password’ in above screen following will be opened:

5.2.8 Select the ‘package’ from the above window options and following option shall be opened:

5.2.9 Select the ‘package maintenance’ from above window and following screen will be displayed:

5.2.10 Select ‘create new package’ and fill the parameters details as:

5.2.11 Enter product name against ‘description’ option, put a good filled carton/bottle on plate form and enter weight against the ‘target weight’ option, enter the total length of product against the ‘product length’ in window.

5.2.12 Select ‘apply’ option from the window.

5.2.13 DYNAMIC COMPENSATION:

5.2.13.1 Select the ‘home’ key from the first window then select ‘packages’ then ’active packages’ from continuous displayed window.

5.2.13.2 Select the ‘dynamic calibration’.

5.2.13.3 Now check that checkweigher platform is clear from any object and then select ‘confirm’ key from the window.

5.2.13.4 Start the motor by selecting the ‘start’ key.

5.2.13.5 Further select the ‘start’ button against the ‘test cycle’ and this leads conveyor to run.

5.2.13.6 Now pass the normally packed single product for 10 times through the conveyor belt.

5.2.13.7 After this select the ‘apply’ button and dynamic compensation shall be completed.

5.2.13.8 Now machine is ready for operation.

5.2.14 Conveyor belt speed:

5.2.14.1 Select ‘menu’ then ‘set up’ then ‘system’ then ‘motor-speed’ option from the continuous displayed window as below:

5.2.14.2 Enter the machine speed which required for product.

5.2.15 Target weight: Feed the required value by numeric keys. (Target weight = average weight of 20 filled carton/filled bottled)

5.2.16 Upper limit setting for filled and sealed bottle: Feed the required value by numeric keys. (Upper limit = average weight of 20 filled carton/bottle + 1g)

5.2.17 Lower limit setting for filled and sealed bottle: Feed the required value by numeric keys. (Lower limit = average weight of 20 filled carton/bottle – 1 g)

5.2.18 Upper limit setting for filled carton: Feed the required value by numeric keys.(Upper limit = target weight of filled carton + 50% of the average weight of 20 good strip/pouch/leaflet (lesser weight entity considered for upper weight limit).

5.2.19 Lower limit setting for filled carton: Feed the required value by numeric keys. (Lower limit = Target weight of carton - 50% of the average weight of 20 good strip/pouch/leaflet (lesser weight entity considered for lower weight limit).

5.3 Rejection Mechanism:

5.3.1 Select the ‘menu’ button from the window then select ‘set up’ then ‘user’ and then ‘system’ in next proceeding window.

5.3.2 Now select the ‘rej. System’ key then select the ‘rej 1’ also select the ‘edit’ button and following window shall be opened:

5.3.3 By trial and error method enter the value against the ‘duration’ option given window so that ejector will reject the upper or lower weighted carton/bottle into rejection box.

5.4 OPERATION:

5.4.1 Remove the ‘CLEANED’ status label and affix “UNDER PROCESS “label on the machine.

5.4.2 Open the compressed air valve and ensure that the compressed air pressure should not be less than 3 Kg/cm².

5.4.3 Follow the point no. 5.2.1 to 5.2.9 and then select ‘edit’ option and following window will be displayed:

5.4.4 Then select the required recipe from above window.

5.4.5 Then press ‘0’ icon given on middle right side of window for zero setting.

5.4.6 Before starting the operation ensure that the cartons taken for the setting are removed from the line.

5.4.7 Start the conveyor by following 5.2.13.

5.4.8 Start passing the cartons/bottle on the checkweigher.

5.4.9 Ensure that the tower lamp indications and its rejection mechanism is functioning by passing the carton/bottle with less weight and higher weight as per the frequency given in the BPR.

5.4.10 Tower lamp in case of correct fill value glows green lamp, for lower fill value glows red lamp and higher fill value glows yellow lamp.

5.4.11 At the end of activity, press ‘CONVEYOR STOP’ to stop the conveyor. Switch ‘OFF’ the mains of the checkweigher and close the compressed air valve.

5.4.12 Check the rejection box of the checkweigher after every one hour and check the carton/bottle for correct fill value. If any discrepancy is observed take corrective action.

5.6 CHALLENGE TEST:

5.6.1 Challenge test for filled and sealed bottle:

5.6.1.1 Pass normally filled and sealed bottle through the checkweigher i.e. as per pack size mentioned in BPR.

5.6.1.2 It must be pass through checkweigher and record the observation in Annexure-I.

5.6.1.3 Now remove the cap from bottle and pass this bottle from checkweigher.

5.6.1.4 It must be rejected by checkweigher and fall into rejection box.

5.6.1.5 Record the observation in Annexure-I.

5.6.2 Challenge test for filled carton:

5.6.2.1 Pass good filled carton through the checkweigher.

5.6.2.2 It must be pass by checkweigher.

5.6.2.3 Record the observation in Annexure-I.

5.6.2.4 Now remove the one lesser weight entity from the carton

e.g. strip/blister/leaflet/pouch which is applicable for lower weight limit setting.

5.6.2.5 Pass this carton through the checkweigher.

5.6.2.6 Carton must be rejected and fall into rejection box by checkweigher.

5.6.2.7 Record the observation in Annexure-I.

5.6.2.8 Now add the one lesser weight entity into carton. e.g. strip/blister/leaflet/pouch which is applicable for upper weight limit setting.

5.6.2.9 Pass this carton through the checkweigher.

5.6.2.10 Carton must be rejected and fall into rejection box by checkweigher.

5.6.2.11 Record the observation in Annexure-I.

FREQUENCY: AT START, AFTER EVERY FOUR HOUR OF OPERATION, AFTER ANY MAINTENANCE WORK AND AT END OF OPERATION

6.0 ABBREVIATION (S):

SOP : Standard operating procedure

SS : Stainless Steel

IPA : Iso Propyl Alcohol

Q.A. : Quality Assurance

V/V : Volume/ Volume

LED : Light emitting diode

7.0 RERERENCE (S):

SOP: Making entries in equipment usage and Cleaning Log sheet.

8.0 ANNEXURE(S):

Annexure-I: Challenge test for checkweigher (Model: MT-S), Make: Mettler Toledo)

9.0 DISTRIBUTION:

9.1 Master Copy : Quality Assurance

9.2 Controlled Copy (S): Production department, Quality Assurance

9.3 Reference Copy (S) : Production department

ANNEXURE I

CHALLENGE TEST FOR CHECK WEIGHER (Make: Mettler Toledo, Model: MT-S)

.webp)

.webp)