1.0 OBJECTIVE:

To lay down a procedure for Cleaning and Operation of Carton Packing Machine.

2.0 SCOPE:

This procedure is applicable to the Cleaning and Operation of carton packing machine in production (Packing).

3.0 RESPONSIBILITY:

Technical Associate: Cleaning and Operation

Officer and Executive: Supervision for Cleaning and Operation

Officer and Executive IPQA: Line

clearance and SOP Compliance Head Production: SOP Compliance.

4.0 DEFINITION (S):

NA

5.0 PROCEDURE:

5.1 CLEANING:

5.1.1 Replace the ‘UNDER PROCESS’ status label with ‘TO BE CLEANED’ status label with date and sign of the production officer.

5.1.2 Record the cleaning start time in equipment usage log as per SOP.

5.1.3 Remove secondary packing material, blister and foil pieces, cartons and leaflets of previous product present on the carton packing machine.

5.1.4 Remove the stereo of previous product from the printing roller and destroy as per SOP.

5.1.5 Clean the conveyor belt, collator magazine, MMI, utility cables and other parts of machine with the help of clean lint free duster.

5.1.6 Wipe the machine with 70 % V/V IPA.

5.1.7 Replace the ‘TO BE CLEANED’ status label by ‘CLEANED’ status label with date and sign of the production officer / QA officer.

5.1.8 If machine is not used within 72 hours clean the machine “before use” with lint free duster dipped in 70%v/v IPA solution followed by dry lint free duster and dully sign the “CLEANED” label again and record the activity in equipment usage log sheet as per SOP.

5.1.9 Record the cleaning activity in equipment usage log sheet as per SOP.

5.1.10 After completion of operation, clean the equipment within 24 hours if not in use.

5.2 MACHINE SETTING:

5.2.1 Switch on the mains and release the emergency switch.

5.2.2 Open the valve of compressed air.

5.2.3 Switch on the PLC and then MMI screen. And set the machine to set mode for machine setting.

5.2.4 The MMI screen displays.

5.2.5 Press BEGIN, the MMI displays below given screen then switch ‘’ON’’ the carton vacuum, leaflet vacuum, conveyor, blister infeed, guard bypass(Only during machine setting) Inching on(during machine setting).

5.2.6 Press LOG IN and enter the level and pass word as per the authorization.

5.2.7 Now set the following parts of machine given from step 5.2.1 to 5.2.8

5.2.8 Product/Blister Magazine

5.2.8.1 This stores various size of blister.

5.2.8.2 Adjust the side support on conveyer belt as per the width of blister.

5.2.8.3 Change the collator magazine as per the product.

5.2.8.4 Set the number of blister count parameter as per the requirement, from the MMI (in DROP COUNT Option). This releases the selected number of blisters in the cell angle one after another and then magazine swings back to match with the next cell angle.

5.2.8.5 For this press EDIT the screen displays.

5.2.8.6 Set the speed of machine by pressing the SPEED option, number of counts by pressing the DROP COUNT option.

5.2.9 Product/Blister Chain:

5.2.9.1 The chain has pocket angle (cell angles) mounted on it. The product /blisters carried between these angles.

5.2.9.2 Set the distance between the pocket angle (cell angles) width as per the width of product.

5.2.9.3 The product chain is made in two sections one is fixed and another is adjustable.

5.2.10 Product Sensor:

5.2.10.1 This unit senses the product present in cell angle. This sensor senses the metal flat only when required number of blisters is available in the product chain.

5.2.10.2 If no blister is available or it is less than the required number of blisters, carton will not pickup and product pusher will not operate.

5.2.10.3 Adjust the height of product sensor with respect to number of blister height.

5.2.10.4 Adjust the height of blister top support guide with respect to number of blister height.

5.2.11 Carton Magazine:

5.2.11.1 This unit stores the cartons.

5.2.11.2 Set the carton magazine according to the length and width of the carton. The carton withdrawal is controlled by product sensor/leaflet sensor and electromagnet. If the product is missing, no carton is released. This achieved by cutting “off” the vacuum. If product is present in pocket, carton is sucked from the magazine.

5.2.11.3 The carton sucked from the carton magazine, comes down to carton support assembly (with flaps open) and transfer to the carton chain by the pusher.

5.2.12 Carton Chain and Pusher:

5.2.12.1 Carton chain holds and carries the carton while it gets opened, filled and closed.

5.2.12.2 Set the width of carton holder in carton chain as per the length and width of carton.

5.2.12.3 Set the height of top support guide as per the height of carton.

5.2.12.4 Set the adjustable side wall as per the width of carton.

5.2.12.5 Set the height of front and rear flap closers as per the height of carton.

5.2.12.6 Set the side wise position of flap opener finger by loosening the clamping screw of finger and the top most position adjustment by sprocket angular position.

5.2.12.7 Check the correct position by rotating the machine by hand wheel. The finger should open.

5.2.12.8 Change the pusher as per the product. (The pushing phase of the pusher tip should be in line with the pusher rod front face else it might damage the chain plates during rotation). Take pusher chain in center of the cell angle pocket by loosening the respective bolt. For checking rotate the entire pusher unit by hand.

5.2.13 Leaflet Setting;

5.2.13.1 Set leaflet magazine as per the length and width of leaflet.

5.2.13.2 Match the timing of leaflet transfer to leaflet chain by M 6 leaflet unit drive bolt.

5.2.13.3 If no blister or less blister come on product chain then no leaflet will not pick-up.

5.2.14 Stereo Setting:

5.2.14.1 Affix the stereo to the stereo roller.

5.2.14.2 Put two to three drops of ink on ink roller, the ink is transferred from ink roller to stereo roller through transfer roller situated between these two rollers.

5.2.14.3 Adjust the pressure roller as per the thickness of carton to obtain the proper printing.

5.2.15 Rejection Sensor:

5.2.15.1 This sensor senses the metal flat only when required number of blisters is available in the carton.

5.2.15.2 Adjust the height of rejection sensor with respect to number of blister height present in carton.

5.2.15.3 The height of sensor should be 1.0 mm more than the number of blisters present in carton.

5.2.15.4 It will stop the machine with carton having the less or more number of blisters as per the standard.

5.3 PROCEDURE:

5.3.1 Replace the ‘CLEANED’ status label with dully filled and signed ‘UNDER PROCESS’ status label.

5.3.2 Record the Operation start time in the Equipment usage log sheet as per SOP.

5.3.3 Follow the step no. 5.2.1 to 5.2.7.

5.3.9 After setting of machine parameters switch over the machine to RUN MODE by moving the key to the left. Press the start push button given on HMI.

5.3.10 Go to BEGIN option and start the machine as per step no. 5.2.7.

5.3.11 After completion of batch switch off the machine by pushing the “OFF” push button GIVEN ON HMI.

5.3.12 Record the Operation end time in the Equipment usage log sheet as per SOP.

5.3.13 Replace the “Under Process” label with “To Be Cleaned” label. YES

5.4 Precautions:

Only authorized person should run the machine in ‘inch’ mode. Do not run production cycle in ‘inch’

5.4.1 mode.

5.4.2 All safety interlocks are bypassed in ‘inch’ mode.

5.4.3 For machine operation the compressed air pressure should not be less than 6 kg/cm².

5.4.4 Do not operate the machine with out proper earthing.

5.5 SETTING OF PHARMA CODE READER FOR CARTON AND LEAFLET:

5.5.1 Pharma code setting for carton (Camera setting 1):

5.5.2 Ensure that “PACKi2CAM" print check system is cleaned.

5.5.3 Get the line clearance by Quality Assurance.

5.5.4 Switch ON the mains. Switch ON the console unit by pressing SW on the RIGHTSIDE wall of the console unit. Check “MCB” left side wall of the console unit.

5.5.5 “PACKi2CAM” screen will be displayed asking for login name and password.

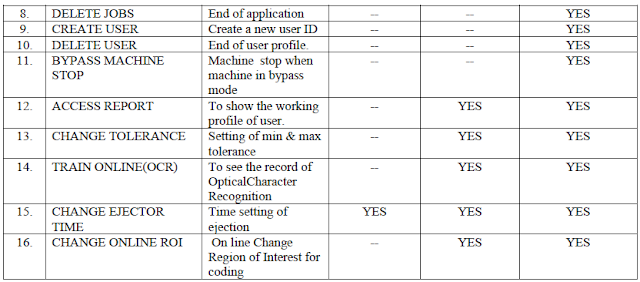

5.5.6 System show 3 types of login levels and they have a specific right assignment.

5.5.7 Following tables given below according to user rights.

5.5.8 Then system will go in learn MODE. Operator pass the carton; image will displayed on the screen by adjusting label gap sensor image position (horizontal can be adjusted).

5.5.9 To start fresh job it will display learn mode as waiting for carton.

5.5.10 Press the carton on the conveyor. Check camera, flash, trigger position, Adjust proper light, no wrinkle or sag on label.

5.5.11 Then screen will display “PLEASE SET IMAGE AND PRESS OK BOTTON” if image is ok then press OK (Rotate image by clicking on the rotate button to set angle (0,90,180, and 270)) if image displayed is seen rotate and then press OK.

5.5.12 The screen will display “Please give the area of reference”. Then supervisor gives AREA (ROI) & press OK button.

5.5.13 To set various function (Pharmacode, 2d code, Barcode present OCR follow procedure given ahead.

5.5.14 In option window click on Pharmacode option: green indicator of Pharmacode will glow. Pop up window will be displayed.

5.5.15 Pharmacode value directly feed it or else to find value click on the bar code indicator. Choose thin and bar as seen in the image so that same combination of bar is produced. It will give Pharmacode value in value indicator. Click direction arrow, value will change. Select appropriate direction and click OK and press ‘CLOSE’ to return main screen.

5.5.16 Give ROI on Pharmacode. In right centre in preview window mage of Pharmacode will be displayed. This bar code should be always vertical, if it is horizontal use rotate button and set the vertical by giving proper angle. Pharmacode value is displayed in left bottom.

5.5.17 Press test button to check the Pharmacode value if Pharmacode value is wrong then it shows “Pharma value is hard to analyze. Give proper ROI or press direct button”. If Pharma value is scanned successfully. Then it shows “Pharma value is scanned successfully”. Press OK button to exit

Pharma setting.

5.5.18 For ejector system of cam 1, label/product must be have zero value.

5.5.19 ENTERING JOB NAME:

5.5.20 Click on text box ‘JOB NAME’. Keypad will appear ENTER job name with the help of keypad. If job name already exist system will ask for re-entering the job name. After click OK keypad will appear again. Enter new job name and press OK to return main menu.

5.5.21 Click on ECS option and window will open with avg. time value.

5.5.22 Now pass approx six carton in front of camera and a value will comes.

5.5.23 Now click on load option and then select ‘’OK’’.

5.5.24 LOAD FROM PREVIOUS JOB:

5.5.25 Click load button and give job name and click OK button to return main screen. Press start button to run the job.

5.6 SELECTION OF MACHINE STOP OR EJECTION CONTROL:

5.6.1 Stop entire machine or can eject the fault carton. Click on eject control system control box will appear on the right side of screen. Enter no. of blister between camera and blister gap sensor. Click OK to return main menu. (if cam2 tab active while clicking on setting button function then the set values will be applicable for camera 2)

5.7 Pharmacode setting for Leaflet (Camera 2):

5.7.1 In option window click on the Pharmacode option; green indicator of Pharmacode will glow. Pop up window will be displayed.

5.7.2 Set the Pharmacode same as Cam 1 as per point 5.5.1.

5.7.3 Set Mini, Rotation, Band values.

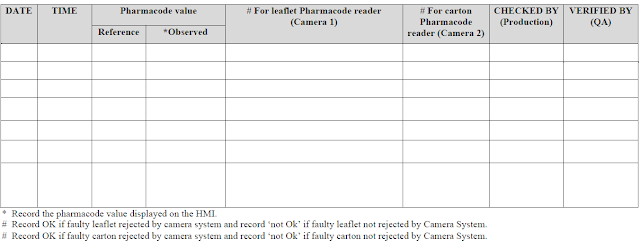

5.8 CHALLENGE TEST FOR PHARMACODE READER:

5.8.1 After setting of Pharmacode reader, Production, QA officer shall take a single carton of product, which has to be printed.

5.8.2 Pass that carton through machine, it should pass through the machine and get printed.

5.8.3 Now mark one or two extra lines in Pharmacode.

5.8.4 Now again pass this carton with extra line through machine.

5.8.5 The machine shall the rejected carton by ejector mechanism in to rejection box.

5.8.6 This challenge test shell be performed before starting printing and as per frequency in BPR and at end of operation of any batch.

6.0 ABBREVIATION (S):

SOP : Standard Operating Procedure

MMI : Man-Machine Interface

PLC : Programmable Logical control

No. : Number

SOP : Standard Operating Procedure

v/v : Volume / Volume

% : Percentage

ROI : Region Of Interest

OCR: Optical Character Recognition.

7.0 REFERENCES:

SOP: Making entries in equipment usage and Cleaning log sheet SOP: Destruction of Rubber Stereos

SOP: Restricted use (Password protected) of system

8.0 ANNEXURE (S):

Nil

9.0 DISTRIBUTION:

Master Copy : Quality Assurance

Controlled Copy (S): Production department, Quality Assurance

Reference Copy (S) : Production department

ANNEXURE I

CHALLENGE TEST FOR PROPIX CAMERA SYSTEM (PACK i 2) FOR SCANNING OF CARTON & LAFLET

ANNEXURE II

Cleaning and operation of Autocartonator machine (Model: HI-CART) with Propix camera inspection

system for pharma code scanning of carton and leaflet (PACK i 2)

.webp)

.webp)