In this post Standard Operating Procedure Cleaning and Operation of Sifter Cum Multi-mill in Pharmaceuticals is describe.

1.0 OBJECTIVE:

To lay down a procedure for cleaning and operation of Sifter cum Multi-mill.

2.0 SCOPE:

The procedure is applicable to the Cleaning and Operation of Sifter cum Multi-mill in Production department.

3.0 RESPONSIBILITY:

Technical Associate : Operation

Officer/ Executive Production: Supervision

Head Production : SOP Compliance

IPQA : SOP Compliance

4.0 DEFINITION (S):

NA

5.0 PROCEDURE:

5.1 “TYPE A” CLEANING:

At the end of shift, change over from one batch to next batch of the same product, same potency and of similar product with ascending potency provided the color is same.

5.1.1 Affix dully filled “TO BE CLEANED” status label on equipment with date and signature of the Production Officer as per SOP.

5.1.2 Ensure that power supply is turned “OFF”.

5.1.3 Remove the loosely adhered powder from the equipment with the help of vacuum cleaner/dust extractor followed by wiping with a dry lint free cloth.

5.1.4 Collect all the powder and dispose it in IPQA disposal waste bin.

5.1.5 Remove the screen from the sifting and milling chamber and clean the screen with vacuum cleaner followed by wiping with a dry lint free cloth.

5.1.6 Check and ensure the integrity of the Screen as per SOP.

5.1.7 Ensure that the equipment is visually clean.

5.1.8 Replace the “TO BE CLEANED” status label with “CLEANED” status label with date and signature of the Production Officer as per SOP.

5.1.9 Clean the area as per SOP.

5.1.10 Record the cleaning observations in the equipment usage log sheet as per SOP.

5.1.11 Record the cleaning observations of screens in the screen utilization and cleaning record.

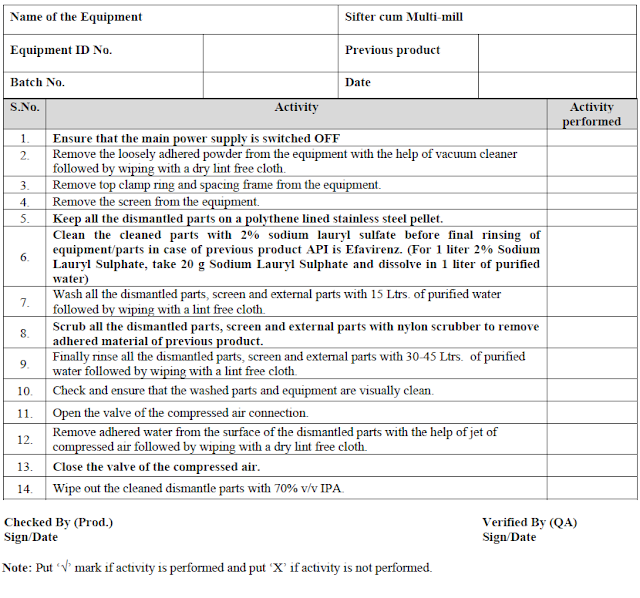

5.2 “TYPE B” CLEANING:

During changeover of product with different actives / color / descending potency or after maintenance of contact parts.

5.2.1 Ensure that power supply is turned “OFF”.

5.2.2 Remove and destroy “TO BE CLEANED” label and affix “UNDER CLEANING” label.

5.2.3 Remove the loosely adhered powder from the equipment with the help of vacuum cleaner followed by wiping with a dry lint free cloth.

5.2.4 Remove top clamp ring and spacing frame from the equipment.

5.2.5 Remove the screen from the equipment.

5.2.6 Keep all the dismantled parts on a polythene lined stainless steel pellet.

5.2.7 Wash all the dismantled parts, screen and external parts with 15 Ltrs. of purified water followed by wiping with a lint free cloth.

5.2.8 Scrub all the dismantled parts, screen and external parts with nylon scrubber to remove adhered material of previous product.

5.2.9 Clean the cleaned parts with 2% sodium lauryl sulfate before final rinsing of equipment/parts in case of previous product API is Efavirenz. (For 1 liter 2% Sodium Lauryl Sulphate, take 20 g Sodium Lauryl Sulphate and dissolve in 1 liter of purified water)

5.2.10 Finally rinse all the dismantled parts, screen and external parts with 30-45 Ltrs of purified water followed by wiping with a lint free cloth.

5.2.11 Check and ensure that the washed parts and equipment are visually clean.

5.2.12 Open the valve of the compressed air connection.

5.2.13 Remove adhered water from the surface of the dismantled parts with the help of jet of compressed air followed by wiping with a dry lint free cloth.

5.2.14 Close the valve of the compressed air.

5.2.15 Wipe out the cleaned dismantle parts with 70% v/v IPA.

5.2.16 Check and ensure the integrity of the sieves as per SOP.

5.2.17 Assemble all the parts to the sifter cum multi-mill.

5.2.18 Clean the electrical cables and other non-contact parts with 70% IPA followed by wiping with a clean and dry lint free cloth.

5.2.19 Clean the area as per SOP.

5.2.20 Affix duly filled and signed “CLEANED” label on the equipment.

.webp)