In this post Standard Operating Procedure of Transfer of Finished Product to Finished Goods Store in pharmaceuticals is describe.

1.0 OBJECTIVE:

To lay down a procedure for transfer of finished product to finished goods stores.

2.0 SCOPE:

This procedure is applicable for transfer of finished product to finished goods stores in production department.

3.0 RESPONSIBILITY:

Officer, Executive, Production – For preparation of Finished Goods Transfer Note

Officer, Executive, IPQA : Verification of Finished Goods Transfer Note before transfer of product

Officer/ Executive, Stores : Verification of FGTN on receipt

Head, Production: Compliance to procedure

4.0 DEFINITION(S):

NA

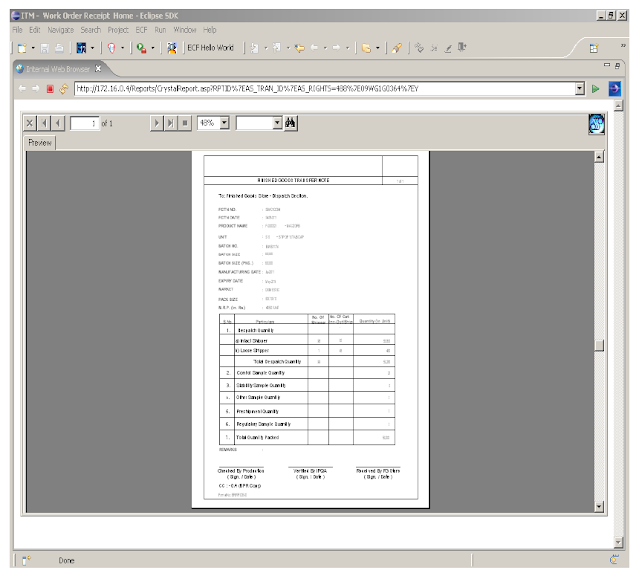

5.1 After completion of packing activity in a day shift enter the Finished goods quantity in ERP (WORK ORDER RECEIPT) as per following procedure.

5.1.1 Enter the FG Work Order in the work order field.

5.1.2 Verify the EXP Date as per the BMR / BPR in the Receipt and change if needed.

5.1.3 Enter the total Packed quantity which includes the entire sample in Rec. quantity field. Enter the MRP of the Product in MRP field.

5.1.4 Select the appropriate Location code and Appr. Location with the help of popup.

5.1.5 Enter the EMRN Status in the field.

5.1.6 Enter the Quantity in Despatchable Qty., Control sample Qty., Stability Sample Qty., Other Sample Qty. and Preshipment Qty., and Regulatory Sample Qty. (if required) in there respective field as per given preview.

5.1.7 Check all the filled entry in the ERP.

5.1.8 Save and Confirm the Receipt by verifying the print preview of FGTN.

5.2 Take double print and after Verification by IPQA, Transfer the packed quantity to the Finished goods store. The entry for the day shall be recorded with the FGTN no. in the Batch Packing Record.

5.3 If the last shipper has the quantity with less than the mention quantity, stamp shipper ‘LOOSE PACK’. Strike out the quantity preprinted on the shipper label and write the actual quantity and production officer and QA officer to sign on the label. Intimate IPQA to verify the packed goods to be transferd to finished goods stores. Record in BPR.

5.4 Last FGTN for a batch shall be prepared after reconciliation of the packing activity.

5.5 On receipt of FGTN, Stores officer/ In charge shall verify the quantity received on the transfer note and transfer the goods to finished goods strores.

5.6 Store Officer/ In charge shall endorse the FGTN. One copy of FGTN shall be retained by stores and the second copy of same shall be attached in the BPR.

5.7 All the details of FGTN like date, FGTN No. and quantity shall be recorded in the BPR.

6.0 ABBREVIATION(S):

BPR : Batch Packing Record

FGTN : Finished Goods Transfer Note No. : Number

7.0 REFERENCE(S) :

NA

8.0 ANNEXURE(S):

Annexure-I : Finished Goods Transfer Note

9.0 DISTRIBUTION:

9.1 Master copy : Quality Assurance

9.2 Controlled copy( S) : Production department , Quality Assurance

9.3 Reference copy (s) : Production department (2 copy)

.webp)

.webp)