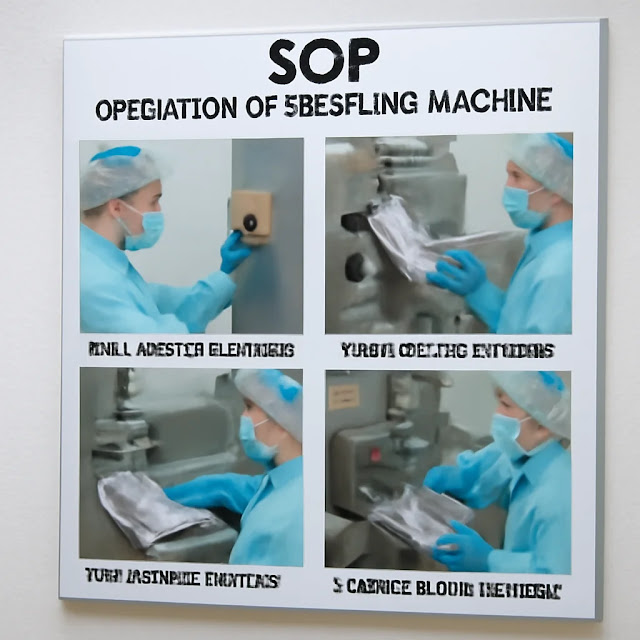

In this post Standard Operating Procedure of SOP for Operation of Defoiling machine in Pharmaceuticals is describe.

Purpose: To lay down operating procedure for the operation of defoiling machine.

Scope: This procedure is applicable for ..............

Responsibility: Production Chemist

To supervise the activity

Pre-operating Check: Check no packing material or residue of previous product should be there.

Equipment used: Blister-defoiling machine

Strip defoiling machine

Operating procedure:

1. Check the cleaning defoiling machine and surrounding area. Floor should be clean and there should not be any residual left over previous product.

2. The strip/ blister packs, which are rejected, taken for defoiling.

3. Start the ON switch of the m/c so that the m/c will start. Insert one by one strips inside the defoiler so that the Aluminum and PVC part will cut away and the tablets insides will come out and collected from the side channel of the m/c to the plastic bag and collect all rejected tablets from the product and Batch specific strips.

4. Place the label on plastic bag as “RECOVERABLE REJECTED “and may be use for any further process. After careful inspection of tablets.

5. Clean the Defoiling m/c, as per Standard Cleaning Procedure.

.webp)

%20Web%20of%20pharma%20.webp)