In this post Standard Operating Procedure of Sanitization of Drain Points in pharmaceuticals is describe.

1.0 OBJECTIVE:

1.1 To lay down a procedure for the sanitization of drain points

2.0 SCOPE:

2.1 The procedure is applicable to the sanitization of drain points in production area.

3.0 RESPONSIBILITY:

3.1 Technical Associate : Cleaning and sanitization of drain point.

3.2 Officer and executive : For verification and implementation of SOP

3.3 Manager : For verification and implementation of SOP

4.0 DEFINITION (S):

4.1 NA

5.0 PROCEDURE:

5.1 Sanitization of Drain Points.

5.1.1 Clean the drain with nylon scrubber followed with purified water.

5.1.2 Pour 500 ml of 2.5% v/v disinfectant solution (Dettol/Savlon) solution in the drain and allow the solution to remain for at least 15 minutes in the drain points. (The procedure of pouring of the 2.5% disinfectant solution (Dettol/Savlon) shall be done from the wash basin in the area where the wash basin is provided).This procedure is done so that the pipes of the wash basin shall also be disinfected.

5.1.3 Use freshly prepared disinfectant solution.

5.1.4 Sanitize the drain points at the end of the day.

5.1.5 Record the sanitization activity in the given Annexure –I.

Note. Use Disinfectant Savlon/ Dettol in every alternate week.

6.0 ABBREVIATION (S):

6.1 v/v : Volume by Volume

6.2 ml : Milliliter

6.3 Ckd : Checked

7.0 REFERENCE (S):

7.1 Approved layout for drain points.

7.2 No of drain points in respective areas.

8.0 ANNEXURE (S):

9.0 DISTRIBUTION:

9.1 Master Copy (S): Quality Assurance

9.2 Controlled Copy (S) : Production department, Quality Assurance, Store

9.3 Reference Copy (S) : Production department, Quality Assurance, Store

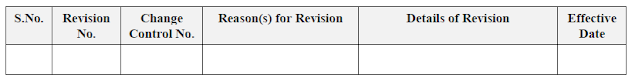

10.0 REVISION HISTORY:

.webp)

.webp)