In this post Standard Operating Procedure of Coding of Accessories in Pharmaceuticals is describe.

Vernacular SOP: No

1.0 OBJECTIVE:

1.1 To lay down a procedure for coding of accessories.

2.0 SCOPE:

2.1 The procedure is applicable to the coding of accessories in production department.

3.0 RESPONSIBILITY:

3.1 Technical associate, Officer Executive :Cleaning and Operation

3.2 Officer and Executive :Supervision

3.3 Manager :SOP compliance

4.0 DEFINITION (S):

4.1 Accessories. Accessories: sieves, screens, FBD/FBP finger bag and RMG filter bag, scoops, racks, blender bin, In-process SS Containers, SS Jar etc. in production area.

5.0 PROCEDURE:

5.1 PROCEDURE TO BE FOLLOWED FOR ALLOTTING CODE NUMBER OF SIEVES, SCREEN AND RETENTION SCREEN OF FLUDIZED BED PROCESSOR:

5.1.1 Eight characters shall be considered as code number of sieve or screen, written as follows:

X: Indicates department of Liquid / Tablet / Capsule for Block-N2 such as ‘G” Trans for GB1,

“GE” trans for GB2 and “G3” trans for GB3. Y: Indicates sieve or screen such as follows. S: for sieve of sifter.

M: for screen of Multi mill. T: for sieve of Turbo sifter.

O: for screen of Oscillator Granulator. C: for screen of Co-mill/super mill.

R: for Retention screen of Fluidized.

Example 1: GS014-01 G: Stands for Tablet Department

S: Stands for sieve of sifter

014: Sieve size

- : Hyphen

01 : Serial Number

Example 4: GM2.5-01

G: Stands for Tablet Department

M:Stands for screen of Multi mill

2.5:Screen size

-:Hyphen

01: Serial Number

Example 7: GT1.5-01

G: Stands for Tablet Department

T: Stands for sieve of Turbo sifter

1.5: Sieve size

-: Hyphen

01 :Serial Number

Example 10: GO0.5-01 G:Stands for Tablet Department O:Stands for screen of Oscillator Granulator

0.5:Screen size

-:Hyphen 01:Serial Number

Example 13: GC1.5-01

G : Stands for Tablet Department C: Stands for screen of Co- mill/super mill

Example 2: GES014-01 GE: Stands for Tablet Department of expansion S: Stands for sieve of sifter

014: Sieve size

-: Hyphen

01: Serial Number

Example 5: GEM2.5-01 GE: Stands for Tablet Department of expansion

M:Stands for screen of Multi mill

2.5:Screen size

-:Hyphen 01:Serial Number

Example 8: GET1.5-01 GE: Stands for Tablet Department of expansion

T:Stands for sieve of Turbo sifter

1.5:Sieve size

-:Hyphen

01 :Serial Number

Example 11: GEO0.5-01 GE :Stands for Tablet Department of expansion

O:Stands for screen of Oscillator Granulator

0.5 :Screen size

-:Hyphen 01:Serial Number

Example 14: GEC1.5-01 GE : Stands for Tablet Department of expansion C: Stands for screen of Co-

Example 3: G3S014-01

G3: Stands for Tablet Department of expansion GB3 S: Stands for sieve of sifter 014: Sieve size

-: Hyphen

01: Serial Number

Example 6: G3M2.5-01 G3:Stands for Tablet Department of expansion GB3 M:Stands for screen of Multi mill

2.5:Screen size

-:Hyphen 01:Serial Number

Example 9: G3T1.5-01

G3: Stands for Tablet Department of expansion GB3 T:Stands for sieve of Turbo sifter

1.5:Sieve size

-:Hyphen

01: Serial Number

Example 12: G3O0.5-01

G3 :Stands for Tablet Department of expansion GB3 O:Stands for screen of Oscillator Granulator

0.5 :Screen size

-: Hyphen

01: Serial Number

Example 15: G3C1.5-01 G3 : Stands for Tablet Department of expansion C: Stands for screen of Co-

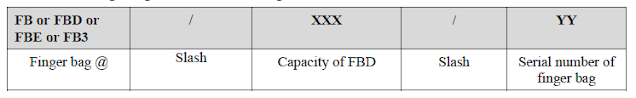

5.2 PROCEDURE TO BE FOLLOWED FOR ALLOTTING CODE NUMBER OF FBD BAG:

5.2.1 FBD finger bag code number will be given as follows:

@ FB/XXX /YY or FBD/XXX/YY or FBE/XXX/YY or FB3/XXX/YY FB: Indicates Finger bag for GB1

FBD: Indicates Finger bag for Anchor mark FBD of GB1.

FBE: Indicates Finger bag of expansion area GB2. FB3: Indicates Finger bag of expansion area GB3.

Example 1: FB/500/01 Finger bag for GB1.

Example 2: FBD/500/01 Finger bag for Anchor mark FBD.

Example 3: FBE/500/01 Finger bag of expansion area GB2

Example 4: FB3/500/01 Finger bag of expansion area GB3.

5.3 PROCEDURE TO BE FOLLOWED FOR ALLOTTING CODE NUMBER OF RMG FILTER BAG:

5.3.1 RMG filter bag code number will be given as follows:

RMG/XXX/YY or RMG2/XXX/YY or RMG3/XXX/YY or RMGG3/XXXX/YY or RMGE/XXX/YY@

RMG: Indicates Rapid Mixer Granulator for GB1

RMG2: Indicates RMG for GB1

RMG3: Indicates RMG for GB1

RMGE: Indicates Rapid Mixer Granulator Filter bag of expansion area GB2.

RMGG3: Indicates Rapid Mixer Granulator Filter bag of GB3.

Example 1: RMG/600/01

Example 2: RMG2/600/01

Example 3: RMG3/600/01

Example 4: RMGE/600/01

Example 5: RMGG3/1200/01

Note: If the FBD bag Or RMG filter bag is damaged during use or cleaning then next available serial No. will be given to the new bag and should be mentioned in the inventory record.

5.4 PROCEDURE TO BE FOLLOWED FOR ALLOTTING CODE NUMBER OF SS CONTAINER:

5.4.1 Seven characters shall be considered as code number of SS container written as follows:

X: Indicates department of Liquid / tablet / Capsule Block-N2 such as ‘G’.

Y: Indicates Section (P: For Production).

Z: Indicates Container (C), Canisters (D)

Example :1 GPC-001 (For Production) Example :2 GPD-001 (For Production)

G : Tablet Department G : Tablet Department

P : Production P : Production

C : Container D : Canisters

- : Hyphen - : Hyphen

001 : Serial Number 001 : Serial Number

5.5 PROCEDURE TO BE FOLLOWED FOR ALLOTTING CODE NUMBER OF SS SCOOP/ SS JAR:

5.5.1 Seven characters shall be considered as code number of SS scoop/SS Jar written as follows: XXYY-ZZ

XX: Indicates the area code like GR: for granulation.

CO: for Compression CT: for Coating.

RC: for Roll compactor. BL: for Blending.

SM: for sifting and milling area. IN: for inspection area.

PP: for pilot plant. PK: for packing area. LI: for Liquid area.

YY: Serial no area. Like Granulation 01, 02, 03 Etc.

-: Hyphen.

ZZ: Serial no of Jar/Scoops presence in specific area.

Example 1: Coding of scoop/Jar for at granulation-v having 3 numbers scoops or jars then coding will be 1st one is “GR05-01”, “GR05-02”, and “GR05-03”

5.6 PROCEDURE TO BE FOLLOWED FOR ALLOTTING CODE NUMBER OF BIN BLENDER:

5.6.1 Following characters shall be considered as code number of Bin Blender written as follows:

A: Indicates department of tablet/capsule of Block-N2 such as ‘G’.

B: Indicates Bin Blender Such as ‘B’

C: Indicates Capacity Such as 100, 200, 600 & 1200.

Example 1:GB600-01 (For Production)

G :Tablet Department

B :Bin Blender

600 :Capacity

- : Hyphen

01 : Serial Number

Example 2:GB1200-01 (For Production)

G :Tablet Department

B :Bin Blender

1200 :Capacity

- :Hyphen

001 :Serial Number

5.7 PROCEDURE TO BE FOLLOWED FOR ALLOTTING CODE NUMBER OF IPC:

5.7.1 Following characters shall be considered as code number of IPC written as follows:

A: Indicates department of tablet/capsule of Block-N2 such as ‘G’.

B: Indicate IPC Such as ‘I’

C: Indicates Capacity Such as 125 and 200 etc.

5.8 CODING OF SILICON PIPES USED IN COATING AREA:

The silicon pipes used in coating should be product dedicated. Each product should have separate silicon pipes and should be coded with product name and its strength. In case of damage of any part or sub part of silicon pipe, it should be replaced with new silicon pipe.

5.9 PROCEDURE TO BE FOLLOWED FOR ALLOTTING CODE NUMBER OF SQUARE BIN:

5.9.1 Following characters shall be considered as code number of Square bin written as follows:

A: Indicates department of tablet/capsule of Block-N2 such as ‘G’.

B: Indicate Production Such as ‘P’

C: Indicates Square bin Such as ‘E’

Example 1: GPE-001 (For Production)

G : Tablet Department

P : Production

E : Square bin

- : Hyphen

001 : Serial Number

5.10 PROCEDURE TO BE FOLLOWED FOR ALLOTTING CODE NUMBER OF FBP BAG:

5.10.1 FBP finger bag code number will be given as follows:

FBP/XXX /YY/ZZ

FBP : Indicates Finger bag

XXX : Indicates Model

YY : Indicates Serial No.

ZZ : Finger bag 1 of 2 and 2 of 2.

Example 1: FBP/125/01/A1 or FBP/125/01/A2

5.11 PROCEDURE TO BE FOLLOWED FOR ALLOTTING CODE NUMBER FOR CAGE TROLLEY:

5.11.1 Following characters shall be considered as code number of Square bin written as follows:

A: Indicates department of Liquid/tablet/capsule of Block-N2 such as ‘G’.

B: Indicate Production Such as ‘P’

C: Indicates Cage Trolley Such as ‘B’

Example 1: GPT-001 (For Production)

G : Tablet Department

P : Production

T : Cage Trolley

- : Hyphen

001 : Serial Number

5.12 CODING OF LATEX SLEEVES:

5.12.1 The sleeves used in manufacturing area should be product dedicated. Each product should have

separate sleeves and should be coded with product name and its strength.

5.12.2 In case of damage of any part or sub part of sleeves, it should be replaced with new

sleeves.

5.13 PROCEDURE TO BE FOLLOWED FOR ALLOTTING CODE NUMBER OF AIR JET MICRONIZER FILTER BAG:

5.13.1 Micronizer filter bag code number will be given as follows:

AJM/FB /XXX

AJM : Indicates Air Jet Micronizer

FB : Indicates Filter Bag

XXX : Indicates Serial No.

Example 1: AJM/FB/001 or AJM/FB/002.

5.14 PROCEDURE TO BE FOLLOWED FOR ALLOTTING CODE NUMBER OF FILTER BAG FOR PNEUMATIC CONVEYING

SYSTEM:

5.14.1 Pneumatic conveying system filter bags will be numbered as follows:

PCS/FB/XXX

PCS : Indicates Pneumatic conveying System

FB : Indicates Filter Bags

XXX : Indicates serial number

Example 1: PCS/FB/001 or PCS/FB/002

5.15 PROCEDURE TO BE FOLLOWED FOR ALLOTTING CODE NUMBER OF RACKS:

5.15.1 Following characters shall be considered as code number of racks written as follows:

A: Indicates department of Liquid/tablet/capsule of Block-N2 such as ‘G’

B: Indicate Production Such as ‘P’

C: Indicates Rack Such as ‘R

D: Indicated area as primary (P) /Secondary (S).

EE: Indicates as Serial Number of Racks.

Example 1: GPRP-01 (For Production) G :Tablet Department

P :Production

R :Rack

P :Primary Area

- : Hyphen

01 : Serial Number

Example 2: GPRS-01 (For Production) G :Tablet Department

P :Production

R :Rack

S :Primary Area

- : Hyphen

01 : Serial Number

5.16 PROCEDURE TO BE FOLLOWED FOR ALLOTTING CODE NUMBER OF BIN CONTAINING DISCHARGE STATION:

5.16.1 Bin code number will be given as follows: IBC/X/YYY

IBC : - Metcon Bin.

X : Capacity.

YYY : - Serial no of bin

Example: 1250 Liter Metcon bin code as IBC/1250/001.

6.0 ABBREVIATION (S):

6.1 FBD : Fluidized Bed Dryer

6.2 FBP : Fluidized Bed Processor

6.3 RMG : Rapid Mixer Granulator

6.4 SS : Stainless Steel

6.5 SOP : Standard Operating Procedure

6.6 No. : Number

6.7 IPC : Intermediate product container.

6.8 OG : Oscillatory Granulator

6.9 AJM : Air Jet Micronizer

6.10 PCS : Pneumatic Conveying System

7.0 REFERENCE (S):

7.1 NA

8.0 ANNEXURE (S):

8.1 Nil

9.0 DISTRIBUTION:

9.1 Master Copy : Quality Assurance

9.2 Controlled Copy (S) : Production department (03), Quality Assurance (01)

9.3 Reference Copy (S) : Production department GB1 (03), Production department GB2 (03),

Production department GB3 (03),

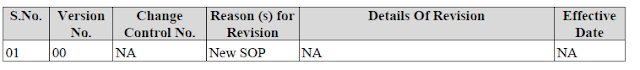

10.0 REVISION HISTORY:

.webp)

%20Web%20of%20pharma%20.webp)