In this post Standard Operating Procedure of Cleaning & Operation of Hot Melt Gum Dispensor in pharmaceuticals is describe.

1.0 OBJECTIVE:

1.1 To lay down a procedure for Cleaning and Operation of Hot Melt Gum Dispenser.

2.0 SCOPE:

2.1 This procedure is applicable for Cleaning and Operation of Hot Melt Gum Dispenser.

3.0 RESPONSIBILITY:

3.1 TTA / TA-Production: Cleaning and operation.

3.2 Officer / Executive- Production: Supervision.

3.3 Officer / Executive-IPQA: compliance of SOP.

3.4 Manager- Production Department: Compliance of SOP.

4.0 DEFINITION:

4.1 NA

5.0 PROCEDURE:

5.1 CLEANING:

5.1.1 Clean Electric cable / Pipes / Out side body with clean dry lint free duster.

5.1.2 Clean the Gum Tank / Gun with Paraffin wax and Vacuum drum by using Hot air gun.

Frequency: After completion of total bulk packing activity or once in six month (whichever is earlier).

5.1.3. Precaution:

5.1.3.1 Use Safety goggles and elbow length size hand gloves during machine cleaning.

5.1.3.2 Do not Over Feed Gum Tank.

5.1.3.3 Keep Machine on stand by position whenever idle.

5.1.3.4 Never use any metal parts for Gum tank cleaning.

5.2 OPERATION

5.2.1 Check the cleanliness of the hot melt gum dispenser.

5.2.2 Switch on the mains from control panel then Plug In the power code.

5.2.3 Open the gum tank and put the gum cake in to the tank ensure that gum tank should not over flow.

5.2.4 Press the parameter key to set temperature of nozzle, pipe and tank.

5.2.5 Set the temperature for hot glue Machine (i.e. Gum Tank / Pipe / Gun) from 160°C to 180°C by pressing

heating switch for 3 second till LED light blinking, then Set the temperature as per BPR. To decrease temperature press “▼” button and to increase temperature press “▲” button.

5.2.6 Wait till temperature achieved up to set point then green light will blink on Gun Tank / Pipe / Gun Symbol.

5.2.7 Start the vacuum pump by pressing key of vacuum motor present on front site of panel.

5.2.8 Set the sensor distance to nozzle that it could dispense gum drop at center of container closure .

5.2.9 Set the Gumdrop by using knob present behind backside of machine.

5.2.10 After completion of Operation switch ‘off’ the mains.

5.2.11 If Machine is idle then keep it on stand by position by pressing stand by button (Ensure green light glowing).

5.2.12 Record the start time and end time of hot melt gum dispenser in the equipment Usage Log Sheet.

6.0 ABBREVATION (S):

6.1 SOP: Standard Operating Procedure

6.2 LED: Light Emitting Diodes

6.3 BPR: Batch Packaging Record

6.4 TTA & TA : Training Technician Associate & Technician Associate.

7.0 REFFERENCES (S):

7.1 SOP, Making entries in equipment usage and cleaning log sheet.

8.0 ANNEXURE (S):

8.1 NA

9.0 DISTRIBUTION

9.1 Master copy : Quality Assurance

9.2 Controlled Copy (S) :Production department (01), Quality Assurance (01)

9.3 Reference copy (S) : Production department (01)

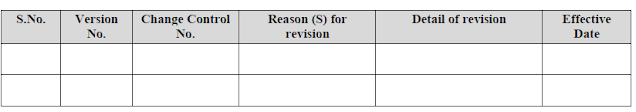

10.0 REVISION HISTORY:

.webp)

%20Web%20of%20pharma%20.webp)