In this post Standard Operating Procedure Cleaning and Operation of Rapid Mixer Granulator (Capacity: 600 Liters) in Pharmaceuticals is describe.

1.0 OBJECTIVE:

1.1 To lay down a procedure for cleaning and Operation of Rapid Mixer Granulator (Capacity 600 Liters).

2.0 SCOPE:

2.1 This procedure is applicable to the Cleaning and Operation procedure of Rapid Mixer Granulator (Capacity 600 Liters) in the Production Area.

3.0 RESPONSIBILITY:

3.1 Technical Associate : Cleaning and Operation

3.2 Production Officer / Executive: Checking cleaning and operation

3.3 Head Production : SOP Compliance

3.4 IPQA Person : Line Clearance

4.0 DEFINITION (S):

4.1 NA

5.0 PROCEDURE:

5.1 “TYPE A” CLEANING:

Change over from one batch to next batch of the same product and same potency and of similar product with ascending potency.

5.1.1 Remove “UNDER PROCESS” label and affix dully filled “TO BE CLEANED” label to the machine.

5.1.2 Enter the cleaning start time equipment usage and cleaning log sheet as per SOP.

5.1.3 Ensure that the main power supply is switched OFF.

5.1.4 Scrub the deposited material of the RMG from inside with the help of S.S. spatula.

5.1.5 Clean the inner and outer side of the RMG with the help of dry lint free duster.

5.1.6 Affix dully filled status label on RMG as “CLEANED” with date and signature of Production Officer verified by QA officer.

5.1.7 Record the cleaning completion time in equipment usage log sheet as per SOP.

5.2. “TYPE B” CLEANING:

Changeover of product with different actives/color/descending potency or after maintenance of contact parts.

5.2.1 Remove “UNDER PROCESS” label and affix dully filled “TO BE CLEANED” label to the machine.

5.2.2 Enter the cleaning start time in equipment usage log sheet as per SOP.

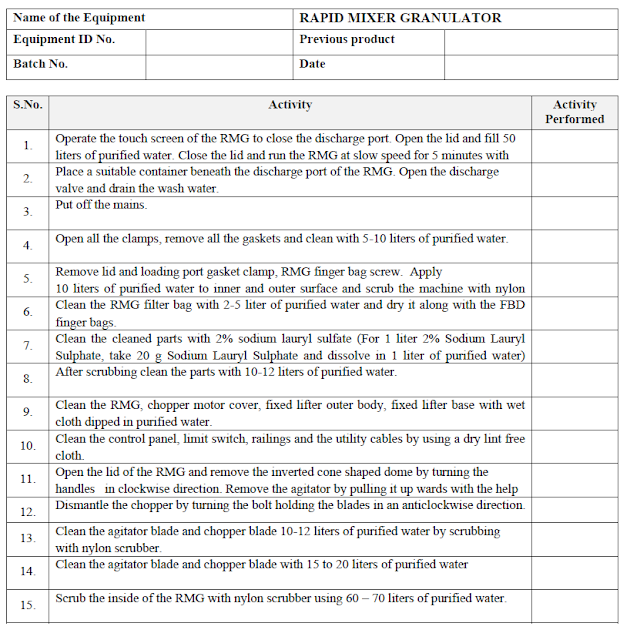

5.2.3 Open all the clamps, remove all the gaskets and clean with 5-10 liters of purified water.

5.2.4 Operate the touch screen of the RMG to close the discharge port. Open the lid and fill 50 liters of purified water. Close the lid and run the RMG at slow speed for 5 minutes with the slow chopper ON.

5.2.5 Place a suitable container beneath the discharge port of the RMG. Open the discharge valve and drain the wash water.

5.2.6 Put off the mains.

5.2.7 Remove lid and loading port gasket clamp, RMG finger bag screw. Apply 10 liters of purified water to inner and outer surface and scrub the machine with nylon scrubber.

5.2.8 Clean the RMG filter bag with 2-5 liter of purified water and dry it along with the FBD finger bags.

5.2.9 Clean the clean parts with 2% sodium lauryl sulfate (For 1 liter 2% Sodium Lauryl Sulphate, take 20 g Sodium Lauryl Sulphate and dissolve in 1 liter of purified water) before final rinsing of equipment/parts in case of previous product API is …………...

5.2.10 After scrubbing clean the parts with 10-12 liters of purified water.

5.2.11 Clean the RMG, chopper motor cover, fixed lifter outer body, fixed lifter base with wet cloth dipped in purified water.

5.2.12 Clean the control panel, limit switch, railings and the utility cables by using a dry lint free cloth.

5.2.13 Open the lid of the RMG and remove the inverted cone shaped dome by turning the handles in clockwise direction. Remove the agitator by pulling it up wards with the help of handles provided. Remove the agitator blades with the help of a Teflon hammer.

5.2.14 Dismantle the chopper by turning the bolt holding the blades in an anticlockwise direction.

5.2.15 Clean the agitator blade and chopper blade 10-12 liters of purified water by scrubbing with nylon scrubber.

5.2.16 Clean the agitator blade and chopper blade with 15 to 20 liters of purified water

5.2.17 Scrub the inside of the RMG with nylon scrubber using 60 – 70 liters of purified water.

5.2.18 Scrub the outside, lid and platform of RMG with a nylon scrubber using purified water.

5.2.19 Unscrew the panel covering on the front side and the side covers. Dry clean the machine from inside using vacuum cleaner and dry lint free duster. Clean underneath the rapid mixer granulator. Clean the side cover by using purified water with nylon scrubber. Fit the panel covering and side covers back in place.

5.2.20 Wash the discharge port by scrubbing the area with a nylon scrubber using 10-15 liters of purified water.

5.2.21 Rinse the agitator, chopper, discharge valve, inside lid, outside and platform of the RMG with 30 – 45 liters of purified water.

5.2.22 Reassemble the agitator blades, dome and chopper assembly in reverse order of dismantling.

5.2.23 Ensure that area is cleaned as per SOP.

5.2.24 Wipe out the all parts of RMG with a clean dry lint free duster. Wipe with 70%v/v IPA and cover the discharge port with help of a polyethylene bag. Put on the mains and operate the touch screen to close the discharge valve and top lid.

5.2.25 Replace the “TO BE LEANED” status label with the “CLEANED” status label with date and signature of Production Officer and QA Officer.

5.2.26 Record the cleaning completion time in equipment usage log sheet as per SOP.

5.2.27 Record the cleaning activity in Annexure-I.

5.3 Frequency:

5.3.1 Type ‘A’ cleaning is applicable after completion of every batch of same product, same potency and of similar product with ascending potency. If same product is processed for more than seven days then follow the procedure of type – B cleaning as per SOP.

5.3.2 Type ‘B’ cleaning is applicable in case of changeover of product with different actives/color/ descending potency or after maintenance of contact parts or same product is run for more than seven days cleaning Type - B done after completion of batch as per SOP.

5.3.3 Cleaning is applicable in case of at the end of working day, dedusting of machine with vacuum cleaner or dry by lint free cloth.

NOTE: After Type - B cleaning, if machine is not used within 72 hours, clean the machine “before use”, with the lint free duster dipped in 70% v/v IPA solution followed by dry lint free duster and dully sign the “CLEANED” label again. Record the activity in equipment usage log sheet as per SOP.

5.4 OPERATION:

5.4.1 Machine Setting:

5.4.1.1 Ensure that the equipment and area is cleaned. Affix ‘UNDER PROCESS’ label dully filled and signed on the equipment and record the observation in the

5.4.1.2 Ensure that the compressed air and main electric supply is ‘ON’ from service Area and Ensure discharge valve is closed.

5.4.1.3 Turn Control ‘ON/OFF’ switch on control panel to ‘ON’ position. Opening screen will open on MMI.

5.4.1.4 Ensure that Compressed air pressure on pressure gauge is approximately 4 Bar If not, adjust by turning Lock knob in clockwise direction to increase the Pressure and anticlockwise to

decrease the pressure.

5.4.1.5 Check the integrity (intactness) of all gaskets before and after use. If gasket found damage (not OK), it is handled through the Un Deviation procedure as per SOP.

5.4.2 Recipe Edit / Load:

5.4.2.1 Touch ‘LOGIN’ ON MMI. Keypad screen will open. Enter correct password.

5.4.2.2 Main menu screen will open. Touch ‘MODE OPERATION’ on MMI. Operation mode main screen will open.

5.4.2.3 Touch ‘AUTO’ on MMI. Auto mode main screen will open. Touch ‘RECIPE’ on MMI. Recipe Parameter ¼ screen will open.

5.4.2.4 Load Mixing-1time, Delay-1 time, Mixing-2 time, Delay-2 time, and Mixing-3 time as per respective BMR.

5.4.2.5 Touch ‘→’ on MMI. Recipe Parameter 2/4 screen will open.

5.4.2.6 Load Delay-3 time, Binder addition time, Granulation -1 time, Granulation -2 and discharge time as per respective BMR.

5.4.2.7 Touch ‘→’ on MMI. Recipe Parameter 3/4 screen will open.

5.4.2.8 Load impeller motor RPM (55-110), chopper delay time, chopper motor slow/fast/stop as per respective BMR for Mixing-1, Mixing-2, Mixing-3 and Binder addition.

5.4.2.9 Touch ‘→’ on MMI. Recipe Parameter 4/4 screen will open.

5.4.2.10 Load impeller motor RPM (55-110), chopper delay time, chopper motor slow/fast/stop as per respective BMR for Granulation-1, Granulation -2 and discharge cycle. Load end point current as per

respective BMR.

5.4.2.11 Touch ‘→’ or ‘BATCH DATA’ on MMI. Batch data screen will open. Load batch number, lot

number and operator name.

5.4.2.12 Touch ‘SAVE’ ON MMI. Keypad will open. Give suitable name or code for the loaded recipe

touch ‘ENTER’ for confirmation. Warning screen will open with message: 1) Save recipe or 2)

overwrite recipe, if recipe with same name or code already exist. Touch ‘YES’ to save or overwrite

the recipe / ‘NO’ for not saving or overwriting the recipe.

5.4.2.13 To load already exist recipe touch ‘LOAD’ on MMI. Recipe list will open. Select the recipe and touch escape. Warning message ‘Load Recipe’ will appear. Touch ‘YES’ to load the recipe / touch ‘No’ for not loading the recipe.

5.5 Auto Mode Operation:

5.5.1 Select auto on operation mode main screen in step no. 5.5.2. Auto mode main screen will open.

5.5.2 Touch ‘AUTO CYCLE’ on MMI. Auto cycle main screen will open

5.5.3 Select binder addition ‘AUTO/MANUAL’ mode. Touch ‘RESET’ on MMI. Touch ‘START’ ON MMI. Process will start as per set parameters and stop automatically after completion of mixing- 1cycle. Touch ‘→’ on MMI. Process Parameter ¼ screen will open.

5.5.4 Touch ‘START’ to start Mixing-2 cycle. Mixing-2 cycle will start as per set parameters and stop automatically after completion of mixing-2 cycle. Touch ‘→’ on MMI. Process Parameter 2/4 screen will open.

5.5.5 Touch ‘START’ to start Mixing-3 cycle. Mixing-3 cycle will start as per set parameters and stop automatically after completion of mixing-3 cycle time.

Note If set delay time after completion of mixing-1, 2 and 3 cycle is zero, machine will automatically go to next cycle

5.5.6 Add Binder solution and touch ‘START’ on MMI. Granulation will start as per set parameters for granulation-1 and granulation-2 cycle and automatically stop after set time.

5.5.7 CYCLE COMPLETED’ message will display on MMI, if FBD bowl is not present below ‘discharge, otherwise machine will automatically go to discharge mode and on completion of discharge cycle ‘Do You Want to Continue’ message will display onscreen. Touch ‘YES’ if discharge is not completed successfully otherwise touch ‘NO’. Discharge cycle will start as per set parameters and stop after set time. On successful completion of

discharge cycle touch ‘NO’ on MMI. Main screen will open.

5.6 Manual Mode Operation

5.6.1 Select Maintenance on operation mode main screen in step no. 5.5.2 Maintenance Mode main screen will open.

5.6.2 To close and open Top Lid touch ‘CLOSE / OPEN’ respectively.

5.6.3 Touch on PLC. Keypad will open. Select impeller RPM.

5.6.4 Touch and hold ‘JOG’ on MMI. Impeller will run till jog key is engaged

5.6.5 Touch ‘RUN’ to run / stop the impeller.

5.6.6 Touch Chopper motor ‘SLOW’ to run / stop chopper at slow speed. Touch Chopper motor ‘FAST’ to run / stop chopper at fast speed.

5.6.7 Touch Purging Valve ‘ON/OFF’ to ON or OFF the purging air.

5.6.8 Touch spray pump ‘ON/OFF’ to ‘ON/OFF’ the spray pump.

5.6.9 Touch machine guard by pass ‘ON/OFF’ to ON/OFF the guards.

5.6.10 At the end of operation touch ‘MODE OPERATION’ on MMI. Mode selection screen will open.

5.6.11 Touch ‘MAIN MENU’ on MMI. Main menu screen will open.

5.6.12 Touch ‘WELLCOME’ on MMI. Opening screen will open.

5.6.13 Turn ‘OFF’ the control panel and affix ‘TO BE CLEANED’ label dully filled and signed on the equipment.

5.6.14 In case of “AUTO” mode failure during batch processing, machine can be run in “MANUAL” mode to Complete the batch by intimating to QA and Engineering department.

6.0 ABBREVIATION (S):

6.1 IPA : Iso Propyl Alcohol

6.2 SOP : Standard Operating Procedure No. : Number

6.3 S.S. : Stainless Steel.

6.4 V/V : Volume / Volume

6.5 RMG : Rapid Mixer Granulator

6.6 MMI : Man Machine Interface

6.7 SLS : Sodium Lauryl Sulphate

7.0 REFERENCES (S):

7.1 SOP: Making entries in equipment usage and cleaning log sheet.

7.2 SOP: Cleaning of production area.

7.3 SOP: Status Labeling

7.4 SOP: Operation of vacuum cleaner.

8.0 ANNEXURE (S):

9.0 DISTRIBUTION

9.1 Master Copy : Quality Assurance

9.2 Controlled Copy (s) : Production department (1) / Quality Assurance (1)

9.3 Reference Copy (s) : Production department (1)

10.0 REVISION HISTORY

ANNEXURE I

CLEANING CHECKLIST OF RMG (Capacity600 Liters)

.webp)

.webp)