In this post Standard Operating Procedure Cleaning and Operation of Bin Blender (SAAN) (Capacity: 50/100/200/300/400/600/1200 Liters) in Pharmaceuticals is describe.

1.0 OBJECTIVE:

1.1 To lay down a procedure for Cleaning and Operation of Bin Blender (Capacity 50 /100 /200 /300 /400/ 600/1200 liters).

2.0 SCOPE:

2.1 The procedure is applicable to the cleaning and Operation of bin blender (Capacity 50/100 /200 /300/ 400/ 600/1200 liters) in production department.

3.0 RESPONSIBILITY:

3.1 Technical Associate : Cleaning and Operation

3.2 Officer and Executive : Supervision

3.3 Head Production : SOP compliance

3.4 IPQA Person : Line Clearance

4.0 DEFINITION (S):

4.1 NA

5.0 PROCEDURE:

5.1 CLEANING: This is a cleaning procedure applicable for cleaning after completion of every batch or after maintenance of contact parts.

5.1.1 Affix dully filled “UNDER CLEANING” status label on equipment with date and signature of the Production Officer as per SOP (“Status Labeling”).

5.1.2 Ensure that power supply is turned “OFF”.

5.1.3 Dedust the equipment with lint free dry cloth.

5.1.4 Wipe the equipment with 70 % v/v IPA.

5.1.5 Record all the observations in the Equipment usage log sheet as per SOP (“Making entries in equipment usage and cleaning log sheet”).

5.1.6 The cleaned equipment is idle for 72 hours, after this period Wipe all the parts of equipment with 70% v/v IPA solution before use. And should be a counter sign on previous “CLEANED” label by production & QA officer with date as per SOP (“Status Labeling”).

5.1.7 Record the 70 % v/v IPA cleaning time of equipment in equipment usage logbook as per SOP (“Making entries in equipment usage and cleaning log sheet”).

5.1.8 Return air riser filter should be cleaned at the time of cleaning of product cleaning /descending potency /color.

5.2 FREQUENCY:

5.2.1 Cleaning is applicable after completion of every batch of same product or different product.

5.3 MACHINE OPERATION WITH OUT HMI:

5.3.1 Ensure ‘CLEANED’ label duly filled and signed is affixed on the equipment. Ensure cleanliness of equipment and area. Remove the ‘CLEANED’ label and affix it in the respective BMR.

5.3.2 Affix ‘EQUIPMENT STATUS’ label duly filled and signed on the equipment and records all the observations in the Equipment Usage Log Sheet as per SOP (“Making entries in equipment usage and cleaning log sheet”).

5.3.3 Turn ‘ON’ the MAINS to ‘ON/OFF’ key.

5.3.4 Select the mode BLENDER DISABLE and BLENDER ENABLE to operate the machine or turn the selector switch lifting or blend position.

5.3.5 For loading and unloading of bin from the blender press the blue soft key for UP and another blue soft key for DOWN or select up or down switch.

5.3.6 Set the total process time by press the soft keys ‘SET’, ‘UP’, ‘SHIFT’, and ‘ENTER’, as per respective BMR.

5.3.7 At the time of operation speed of blender is set by the knob provided on the panel. Rotate the knob on clockwise direction to increase the speed and on anticlockwise direction to decrease the speed.

5.3.8 Speed of the blender is to be set from 0% to 100% or RPM according to requirement as per BMR.

5.3.9 After setting of time and speed, run the blender by pressing the soft key ‘RUN’. For stop the blender press the soft key ‘STOP’.

5.4 Loading and Unloading of Bin blender:

5.4.1 Load the Blending time and RPM as per respective BMR.

5.4.2 Open the safety railing and insert the bin blender and close the safety railing.

Note: In case of blending area - V, to adjust the height of bin turn the knob right side to lift the bin and left side to down the bin.

5.4.3 Press and hold the ‘UP’. Blender bin start lifting upward. When the blender bin will reach the middle limit switch release the ‘UP’ soft key.

5.4.4 Open the safety railing and insert the bin blender and close the safety railing.

5.4.5 Press and hold the UP/DOWN switch to ‘UP’ position. Blender bin start lifting upward. When the blender bin will reach the middle limit switch release the ‘UP’ switch.

5.4.6 Open the safety railing and remove the trolley and again close the safety railing.

5.4.7 Touch ‘RUN’ soft key to start the operation.

5.4.8 Operation will stop after set time.

5.4.9 For unloading of the lubricated blend UP the blender. Blender bin will start lifting up and stop at the upper limit switch.

5.4.10 Open the safety railing and place IPC below the outlet chute of the blending bin. Open the butterfly valve and unload the bin.

5.4.11 On completion of operation open the safety railing and insert the trolley and again close the safety railing.

5.4.12 Touch ‘DOWN’ on the screen. Blender bin will start lifting down. Touch ‘UP’, if required.

5.4.13 Open the safety railing and remove the blender bin. Close the safety railing.

5.4.14 Turn ‘OFF’ the control key.

5.4.15 Take the blender bin to the ‘Granules Store’ area, if not unloaded.

5.4.16 Affix ‘TO BE CLEANED’ label duly filled and signed on the bin blender.

5.4.17 Affix ‘TO BE CLEANED’ labels duly filled and signed on blender bin, if unloaded.

5.4.18 Record all the observations in equipment Usage Log Sheet as per SOP (“Making entries in equipment usage and cleaning log sheet”).

5.5 MACHINE OPERATION WITH HMI:

5.5.1 Ensure ‘CLEANED’ label duly filled and signed is affixed on the equipment. Ensure cleanliness of equipment and area. Remove the ‘CLEANED’ label and affix it in the respective BMR. Affix ‘EQUIPMENT STATUS’ label duly filled and signed on the equipment and records all the observations in the Equipment Usage Log Sheet as per SOP (“Making entries in equipment usage and cleaning log sheet”).

5.5.2 Turn ‘ON’ the control ‘ON/OFF’ key. Opening screen shall appear within one minute with LOGIN displaying.

5.5.3 Touch ‘Login’ on screen. Keypad will appear on screen. To open the digit keypad touch ‘0-9’. Load the correct password and then touch ‘Enter’ for confirmation.

Note: Three access levels have been provided in the machine

Level 3 meant for recipe edit Level 2 and 1 are for machine operation in auto and manual mode.

5.6 Recipe Edition:

5.6.1 Access level 3. Touch ‘Recipe Edit’ on the screen. ‘Recipe Edit’ screen will appear with following process parameters ‘Product Name, Batch No., Lot No., Operator Name, Recipe No.

5.6.2 Load the Product Name, Batch No., Lot No., as per respective BMR.

5.6.3 Touch ‘NEXT’ icon display on screen. ‘Recipe Edit – 2’ screen will appear with following process parameters ‘Blending- 1 time’, Blending- 1 RPM, ‘Blending- 2 time’, Blending- 2 RPM, ‘Blending- 3 time’, Blending- 3 RPM. Touch ‘NEXT’ icon display on screen, screen will appear with

followingprocess parameters ‘Blending- 4 time’, Blending- 4 RPM, ‘Blending- 5 time’, Blending-5 RPM and save the recipe by touching the ‘SAVE’ icon two times.

5.6.4 Note: Blender RPM is fixed.

5.6.5 Touch ‘Next’ on screen. Enter the respective recipe no. and load the recipe by touching the’ LOAD’ icon.

5.6.6 Touch the ‘BACK’ icon and come back on home screen.

5.7 Auto Mode Operation

5.7.1 Touch ‘Auto mode’ on the opening screen with Operation details. Auto mode main screen will appear with instruction ‘Unlock the Safety Railing and Open the Door’.

5.7.2 Unlock the safety railing and touch ‘OK. Instruction ‘Insert the Bunker’ will display on the screen.

5.7.3 Insert the bunker and lock it firmly. Touch ‘OK’. Instruction ‘Close the Door and Lock the Safety Railing’ will display on the screen.

5.7.4 Close the safety railing such that it will press the railing limit switch. Touch ‘OK’. Instruction ‘Lift the Bunker’ will display on the screen.

5.7.5 Touch the ‘UP’ and ‘DOWN’ icon to adjust the bunker at home position.5.7.6 Lock the safety railing. Touch ‘OK’. Instruction ‘Start the Cycle’ will display on the screen. Touch ‘OK’.

5.7.7 Touch the ‘RECIPE PRINT’ icon for print the operation details.

5.7.8 Touch ‘Start’ on the screen. Cycle will start as per set parameters and stops automatically after set blending time. Next screen will show operation details as Blening-1, follow the same operation as per Blending-1 for further operation if required as Blening-2, Blening-3, Blening-4,

and Blening-5.

5.7.9 Unlock the railing and adjust the trolley below the lifted blender bin. Touch ‘OK’. Instruction ‘Adjust the Trolley and Lower the Bunker’ will display on the screen.

5.7.10 Touch and hold ‘Down’ on screen. Blender bin will start lifting down. Touch ‘Up’ key to lift up the blender bin, if required.

5.7.11 For Blening-2, Blening-3, Blening-4, and Blening-5 operation if required, Open the lid of blender bin and add the lubricant with SS scoop and firmly close the lid. ‘OK. Instruction ‘Insert the Bunker’ will display on the screen.

5.7.12 Insert the bunker and lock it firmly. Touch ‘OK’. Instruction ‘Close the Door and Lock the Safety Railing’ will display on the screen.

5.7.13 Touch ‘Start’ on the screen. To start the Blening-2, Blening-3, Blening-4, and Blening-5 operation if required. Cycle will start as per set parameters and stops automatically after set blending time.

5.7.14 Unlock the safety railing and remove the trolley. Touch ‘OK’ on the screen. Instruction ‘Lock the Safety Railing’ will display on the screen.

5.7.15 Touch and hold ‘Down’ on screen. Blender bin will start lifting down. Touch ‘Up’ key to lift up the blender bin, if required.

5.7.16 Screen will display operation details ‘Lubrication Cycle’ and instruction ‘Unlock the Safety Railing and Open the Door’ will display on the screen.

5.7.17 Unlock the safety railing. Touch ‘OK’. Instruction ‘Remove the Bunker’ will display on the screen.

5.7.18 Remove the blender bin. Touch ‘OK’. Instruction ‘Close the Safety Railing and Lock the Door’ will display on the screen.

5.7.19 Close the safety railing. Touch ‘OK’. Opening screen will appear.

5.8 Manual Mode Operation and Unloading:

5.8.1 Touch ‘Manual Mode’ on the opening screen. Manual mode main screen will appear.

5.8.2 Load the Blending time and RPM as per respective BMR.

5.8.3 Open the safety railing and insert the bunker and close the safety railing.

5.8.4 Touch and hold the ‘Up’. Blender bin start lifting upward. When the blender bin will reach the middle limit switch release the cage up key.

5.8.5 Open the safety railing and remove the trolley and again close the safety railing.

5.8.6 Touch ‘Start’ key to start the operation.

5.8.7 Actual time and RPM will display on screen.

5.8.8 Operation will stop after set time.

5.8.9 Touch and hold ‘ENABLE’ and ‘DISABLE’. Blender bin will start lifting up and stop at the upper limit switch.

5.8.10 Open the safety railing and place IPC below the outlet chute of the blending bin. Open the butterfly valve and unload the bin.

5.8.11 On completion of operation open the safety railing and insert the trolley and again close the safety railing.

5.8.12 Touch ‘Cage Down’ on the screen. Blender bin will start lifting down. Touch ‘Cage Up’, if required.

5.8.13 Open the safety railing and remove the blender bin. Close the safety railing.

5.8.14 Touch ‘Main’ on screen. Opening screen will appear.

5.8.15 Touch ‘Log Out’. ‘You Are Logged Out’. Turn ‘OFF’ the control key.

5.8.16 Take the blender bin to the ‘Granules Store’ area, if not unloaded.

5.8.17 Affix ‘TO BE CLEANED’ labels duly filled and signed on the bin blender.

5.8.18 Affix ‘TO BE CLEANED’ labels duly filled and signed on blender bin, if unloaded.

5.8.19 Record all the observations in equipment Usage Log Sheet as per SOP (“Making entries in equipment usage and cleaning log sheet”). After blend transfer into the bin, bottom valves of the blend bins shall be properly covered with shrink film to prevent bins from surrounding environment.

6.0 ABBREVIATION (S):

6.1 IPA : Iso propyl alcohol

6.2 SOP : Standard Operating Procedure.

6.3 No. : Number

6.4 v/v : Volume/Volume

6.5 BMR : Batch Manufacturing Record

6.6 IPC : In process container

6.7 QA : Quality Assurance

7.0 REFERENCE (S):

7.1 SOP: Making entries in equipment usage and cleaning log sheet.

7.2 SOP: Cleaning of Production area

7.3 SOP: Status Labeling

8.0 ANNEXURE (S):

8.1 NIL

9.0 DISTRIBUTION:

9.1 Master Copy : Quality Assurance

9.2 Controlled Copy (S): Production department (02), Quality Assurance (01)

9.3 Reference Copy (S) : Production department (02)

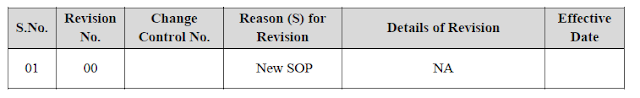

10.0 REVISION HISTORY:

%20(Capacity%20501002003004006001200%20Liters).webp)

.webp)