Working Principle

- Filled capsules of filler are transferred to the lower hopper and the capsules are brought into the sieve drum by the rotating brush rotating at the entrance of the hopper.

- On the sieve drum, use a brush to grind the capsules and remove dust. Caps without caps and separate capsules are taken out through the vacuum on the front of the vacuum.

- The brush sends the capsule to the exhaust port of the screen cylinder.

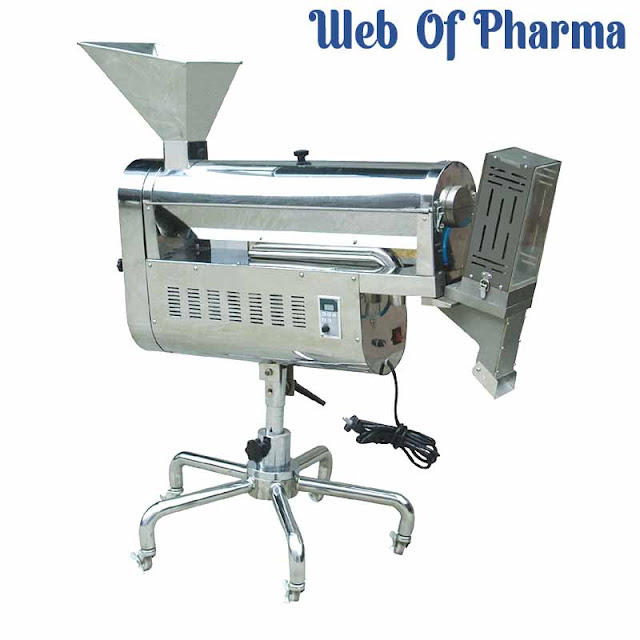

Specification of Capsule Polishing Machine

It can eliminate static electricity. Automatically rejects ultra-light capsules, flakes and empty capsules.

A new type of net cylinder ensures that the capsule is not clogged during operation.

To effectively protect the printed capsules, the capsules do not come into direct contact with the metal net.

The new type of brush is durable and easy to replace.

Excellent design for quick cleaning and easy maintenance. Uses an ideal frequency converter for long-term continuous use

Driven by a synchronous belt to reduce machine noise and vibration

Suitable for caps of all sizes without replacing parts.

All major components are made of premium quality stainless steel and meet pharmaceutical GMP requirements.

.webp)

%20Web%20of%20pharma%20.webp)

.webp)