1.0 OBJECTIVE:

To

lay down the operating procedure of Electronic Analytical Weighing Balance CBK Series-8H Adam.

2.0 SCOPE:

This

shall be applicable to the Electronic Analytical Weighing

Balance CBK Series-8H Adam of Quality Control Instrument Laboratory.

3.0 RESPONSIBILITY:

3.1

Supervisor/

Machine operator.

3.2

Production

Pharmacist.

4.0 ACCOUNTABILITY:

4.1

Manager-Production.

5.0 MATERIAL AND

EQUIPMENT:

5.1

Electronic Analytical Weighing Balance CBK Series-8H Adam.

5.2

Sample.

6.0 PROCEDURE:

6.1

Operation:

6.1.1

Make sure that the

balance/scale is already properly set up.

6.1.2

Level the scale by

adjusting the four feet. The scale should be adjusted such that the bubble in

the spirit level is in the center of the level and the scale is supported by

all four feet.

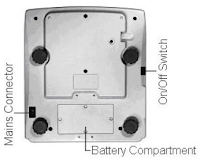

6.1.3

Attach the power

cable to the connection on the base on left of the scale. Plug in the power

cable to the main

6.1.4

Switch on the

power switch located on the base on the night side of the scale.

6.1.5

The scale will

first display the software revision then run a self-test. At the end of the

self-test it will display zero weight when a stable condition has been

achieved.

6.1.6

Before performing

weighing assures that, balance is calibrated.

6.1.7

Zero the scale by

pressing the [Zero]. The zero

indicator will be on. Place a container on the pan and its weight will be

displayed.

6.1.8

Press [Tare] when the reading is stable.

6.1.9

After taring,

place the sample in the container. The display will show the weight and the

unit of weight currently in use.

6.1.10

Auto power off can

be set by the user. So it will power off automatically.

6.1.11

Switch off the

mains when the balance is not in use.

6.2

Precautions:

6.2.1

Install the

balance on a vibration free place.

6.2.2

Check all the

circuits before use.

6.2.3

If during or

before weighing power supply fails, then recalibrate the balance.

6.2.4

Do not blow air

into the chamber under any circumstances.

6.2.5

Never press or

touch the weighing pan during weighing.

7.0 REVISION LOG:

Revision No.

|

Effective Date

|

Reason

|

00

|

New

SOP

|

8.0 REFERENCES:

8.1

Not Applicable.

9.0 ANNEXURES:

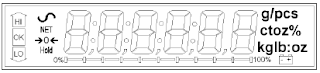

Annexure

1: Overview

of Display and Operating Elements

Annexure:

1

OVERVIEW

OF DISPLAY AND OPERATING ELEMENTS

Overview

of Display and Operating Elements

|

10.0

ABBREVIATIONS:

Abbreviation

|

Expanded Form

|

SOP

|

Standard operating

procedure

|

&

|

And

|

No.

|

Number

|

Ltd.

|

Limited

|

F

|

Format

|

g

|

Grams

|

.webp)

%20Web%20of%20pharma%20.webp)