In this post Standard Operating Procedure Dispensing of Packaging Material in Pharmaceuticals is describe.

PURPOSE:

To provide procedure for Dispensing of Packaging Material.

SCOPE:

Applicable to all procedure to be followed while dispensing of packaging materials on work order, consumption memo and issue slip.

RESPONSIBILITY:

Stores and Production.

DEFINITION:

Dispensing:Dispensing is the issuance of materials to production as per quantities mentioned on the Work Order / Issue Slip / Consumption Memos by following cGMP standards and proper labelling.

1.0 HEALTH, SAFETY AND ENVIRONMENT:

1.1 Switch on the VLAF/UDAF as per the SOP wherever required for dispensing of primary packaging material.

1.2 Wear all the personnel protective equipments e.g. snoods, nose mask, goggles, disposable hand gloves etc. (wherever applicable) while dispensing primary packaging material.

2.0 PROCEDURE:

2.1 Get the Work Order / Consumption Memo / Issue Slip for the Batch to be dispensed in advance. Check the Work Order / Consumption Memo / Issue Slip for Product, Batch No., Export Order No. (If any) and authorisation.

2.2 Check the availability of the released packaging material in SAP system as per work order.

2.3 Ensure that packaging material dispensing area is cleaned before start of the dispensing activity and record the line clearance (Refer SOP).

2.4 Arrange clean SS cage trolley for keeping dispensed printed packaging materials.

2.5 Take the process order no. from work order and do the batch determination in SAP system. After batch determination take the print of proposed work order and dispensing labels for dispensing activity. In case of system breakdown use pre printed dispensing card label.

2.6 Issue the packaging material on FEFIFO basis to the extent practical. While issuing packaging material issue the material sequentially as follows to the extent practical.

2.6.1 Material returned on EMRM.

2.6.2 Loose pack of material.

2.6.3 Intact pack of material.

2.7 Locate the packaging material required for dispensing by referring to the location tracking system.

2.8 Check the material code on Packaging materials. It should match with the material number mentioned on the work order.

2.9 Take out the material of required quantity from the racks on the pallet and shift these pallets to the dispensing area. Dispense the packaging material in the designated packaging material dispensing area only.

2.10 Deface EMRM label by crossing it before dispensing.

2.11 In case of:

2.11.1 Aluminium Foil/ PVC film / PVDC / PE, 3 Ply laminate / 4 Ply laminate: Dispense the aluminium foil/ PVC Film / PVDC / PE, 3 Ply laminate / 4 Ply in the primary packaging material dispensing area. The rolls are weighed to the nearest quantity (which can be more than the required quantity) mentioned in the work order. Record the total quantity of each SAP batch No. on the front side of the work order. Record the quantity of individual rolls along with the SAP batch No., on the back side of work order or annexure provided (whichever is applicable). Affix the dispensing label having all details.

Note: Printed foils should be transferred to production under lock and key.

2.11.2 Printed carton/ catch cover and leaflet: Dispense the printed cartons/ catch cover and leaflets in secondary packaging Material Dispensing area. Count the number of units in the pack manually. Then dispense the required quantity of material as mentioned in the work order, which can be excess extent of one lowest inner pack. Keep the packs of cartons/ catch cover and leaflet in the cleaned S.S. cage under lock and key. Affix the dispensing label duly signed by Stores and Production Officer.

Note: Only intact packs should be issued including QC sampled pack and no loose packs to be issued to production.

2.11.3 Printed labels/plain label: Dispense the printed/plain labels in secondary packaging material dispensing area. Labels in sheet form/ cut form should be dispensed exactly as per the quantity mentioned in the work order to the extent practical. In case of label in roll form (pre numbered) should be dispensed intact to the nearest quantity mentioned on the work order. Record the number of individual quantity of rolls on the back side of the work order or annexure provided. Keep the rolls in the locked cage. Affix the dispensing label for each SAP batch No. dispensed duly checked and signed by Stores and Production Officer.

2.11.4 Plastic containers, caps, polybags and tri laminated polybags: Take out the intact boxes from the respective rack. Dispense the intact packs of plastic containers and caps to the nearest quantity mentioned in the work order in the primary packaging material dispensing area. Dispense

polythene bags and tri laminated polybags by counting the polythene bags and tri laminated polybags as per the quantity mentioned on the work order/Issue slip/consumption memo(whichever applicable) in primary packaging material store. Pack the polybags and tri laminated polybags in the separate polybags. Affix the dispensing label duly checked and signed by Stores and Production Officer.

2.11.5 Silica Gel Bags: Dispense the silica gel bags in primary packaging material dispensing area as per SOP CQA -

348. Dispense silica gel in roll form to the nearest quantity, which can be excess to the extent of one roll than that mentioned on the work order. Dispense the silica gel bag in cut form to exact number of material as per the quantity mentioned in the work order. Record the dispensed quantity

of silica gel on work order. Affix the dispensing label duly checked and signed by Stores and Production Officer.

2.11.6 Cotton (Rayon Sanicoil): Dispense the required quantity of cotton (Rayon Sanicoil) in primary packaging material dispensing area. Dispense the cotton on weight basis to nearest quantity in form of roll as per quantity mentioned on the work order (which can be excess than the required quantity). Affix the dispensing label duly checked and signed by stores and production officer.

2.11.7 Aluminium Containers: Dispense the intact packs of Aluminium containers in primary packaging material dispensing area. Dispense to the nearest quantity (which can be more than the required quantity) mentioned in the work order. Debox the packs. Keep the pack on the clean SS pallet. Wrap the entire pallet. Affix the dispensing label duly checked and signed by Stores and Production Officer.

2.11.8 Valves and Vials: Dispense the intact packs of valves and vials in primary packaging material dispensing area. Dispense to the nearest quantity (which can be more than the required quantity) mentioned in the work order. Debox the packs. Keep the pack on the clean SS pallet. Wrap

the entire pallet. Affix the dispensing label duly checked and signed by Stores and Production Officer.

2.11.9 Nasal Adaptors, Nasal Pump, and Glass Vials: Dispense the Nasal Adaptors / Nasal Pump / Glass Vials under VLAF in packaging material Stores. Dispense to the nearest quantity (which can be more than the required quantity) mentioned in the work order. Debox the packs. Keep the pack on the Pallet/SS Cage/Trolley. Affix the dispensing label duly checked and signed by Stores and Production Officer.

2.11.10 Glass Bottles: Count the required number of intact boxes / trays, which can be excess upto one box / tray, than the quantity mentioned on the work order and place them on clean SS pallet. Wrap them with shrinking film.

2.11.11 LDPE Granules: Dispense the intact pack of the granules, nearest to the quantity (which can be more than the standard quantity) mentioned on the work order. Affix the dispensing label duly checked and signed by Stores and Production Officer.

2.11.12 Plastic Caps: Count the required number of intact boxes, debox the boxes and dispense the same to production as per the quantity mentioned on label by the manufacturer. Affix a dispensing label duly signed by the Stores and Production Officer.

2.11.13 PP Caps: Material to be issued as intact pack after deboxing in the primary packaging material dispensing area under VLAF/UDAF. Transfer the deboxed material in clean fresh double polybag individually sealed. Quantity to be considered as mentioned on the supplier labels.

Dispense the nearest quantity (more than required quantity) mentioned in work order. Affix a dispensing label duly signed by the Stores and Production Officer.

Note:

i Use disposable Hand gloves during deboxing the packs.

ii No damaged pack of sterile, plugs, caps HDPE bottles should be dispensed.

2.11.14 Plain cartons: Dispense the material in secondary packaging material dispensing area, count the number of packs equivalent to the quantity mentioned on the work order and keep directly into the SS cage/ trolley / pallets. Affix the dispensing label duly signed by Stores and

Production Officer.

2.11.15 Shippers/ Partitions/ Plates: Count the exact number of Shippers/ Partitions/ Plates equivalent as per quantity mentioned on the work order. Affix the dispensing label duly checked and signed by Stores and Production Officer.

2.11.16 BOPP Tape: Dispense the exact number of BOPP Tape as per the quantity mentioned on issue slip. Affix the dispensing label duly checked and signed by Stores and Production Officer (If Applicable).

2.11.17 Polypropylene Strap: Dispense exact number of strap rolls as per the quantity mentioned on issue slip. Affix the dispensing label duly checked and signed by Stores and Production Officer (If Applicable).

2.11.18 BOPP film: Dispense the BOPP film rolls, which can be excess than the quantity mentioned on the issue slip / work order / consumption memo to the extent of one roll. Quantity to be considered as mentioned on the supplier labels. Affix the dispensing label duly checked and signed

by Stores and Production Officer.

2.11.19 Actuators: Dispense the actuators in Primary packaging material Stores. Dispense to the nearest quantity (which can be more than the required quantity) mentioned in the work order. Debox the packs. Affix the dispensing label duly checked and signed by Stores and Production Officer. In case the actuators are embossed with the product name or strength it should be transferred to the production under lock and key.

2.11.20 Logo pouch: Dispense the logo pouch in secondary packaging material. The rolls dispensed to the nearest quantity (which can be more than the required quantity) mentioned in the work order. Record the total quantity of each SAP batch No. on the front side of the work order. Record the quantity of individual rolls along with the SAP Batch No. on the work order. Quantity to be considered as mentioned in the supplier labels. Affix the dispensing label having all details.

2.11.21 Hologram: Dispense the hologram in secondary /primary packaging material store (as applicable). Dispense the intact quantity (which can be more than the required quantity) mentioned in work order/consumption memo/issue slip. Affix the dispensing label duly checked and signed by

Stores and Production Officer. It should be transferred to the production under lock and key.

2.11.22 Plastic trays: dispense the material in secondary packaging material store. Dispense the nearest quantity (which should not be less than the standard quantiy mentioned on the work order) to the extent of lowest pack size available on the clean SS pallet / SS cage trolley.

2.11.23 Ice packs: Take out the number of packs to the quantity mentioned on the work order. Dispense the exact number of ice packs after counting in secondary packaging material dispensing area. Dispensing label duly checked and signed by stores and packing officer should be affixed.

Note: Keep the icepacks in deep freezer well in advance before the packaging operation starts for freezing it in hard cake.

2.11.24 Thermocol boxes: Take out the number of boxes to the quantity mentioned on the work order. Dispense exact number of thermocol boxes after counting. Dispensing label duly checked and signed by stores and packing officer should be affixed.

2.11.25 Metallic Seal: Take out the number of packs to the quantity mentioned on the issue slip. Dispense the exact number of metallic seal after counting in secondary packaging material dispensing area. Ensure that metallic seal should be issued serial wise. Dispensing label duly

checked and signed by stores and packing officer should be affixed.

2.11.26 Void treated pet tear label: Dispense void treated pet tear label in secondary packaging material store. The rolls should be dispensed to the nearest quantity (which can be more than the required quantity) mentioned in the work order.

2.12 After dispensing of the material, blue tape should be affixed on the top left corner of the Approved QC status label / manufacturer item details label of the loose pack (if any).

2.13 Stores Officer and Production Officer should check the quantities and sign in respective columns in work order /consumption memo/ issue slip and dispensing labels. Transfer the printed packaging material to the production under lock and key.

2.14 In case of more than one SAP batch Number is to be dispensed, dispense the different SAP batch Number separately and affix separate labels printed from SAP.

2.15 In case if the dispensed material in stacked on more than one pallets, affix one label to each pallet specifying the details of material dispensed, following the sequence mentioned in point

2.14 and same should be recorded on work order.

2.16 If the material is to be dispensed against reservation, confirm that all the relevant material details and reason for material requirement are mentioned on the issue slip and issue slip is authorised.

2.17 Partially dispensed material of the batch should be kept under lock and key at the end of shift to the extent practical. The dispensed materials should be stored under specified storage conditions. Same batch to be continued in next working day should proceed by filling new line clearance and area usage record. Data posting in SAP should be done only after completion of the entire batch.

2.18 Before issue posting in SAP, issue details should be checked with proposed work order and BMR/BRP to ensure correct data posting in the SAP.

NOTE:

i Dispensing of primary packaging material should be done using fresh hand gloves (wherever Applicable).

ii If material is dispensed in polybags, each bag should be individually sealed or tied with fasteners after entrapping the air. Then it should be transferred in S.S. cage / pallet.

iii If the consignment is consumed during dispensing, it should be transferred to Production along with its consignment card and it should be ensured that the EMRM received (if any) of the same consignment should be along with its consignment card.

iv Aluminium containers, valves, plugs, adapters, actuators, sterile material intact bags should not be opened at the time of dispensing.

v In case of batches having large batch size which can not dispensed in a day that can be dispensed in multiple days and same should be recorded in Annexure STP.

vi After completion of batch, immediately transfer the batch to Production area.

3.0 ABBREVIATIONS:

BOPP : Bi-Axially Oriented Poly Propylene

cGMP : current Good Manufacturing Practices

CQA : Corporate Quality Assurance

e.g. : For example

EMRM : Excess Material Return Memo

etc. : Etcetera

FEFIFO : First Expiry First in First Out

HDPE : High density Poly Ethylene

LDPE : Low Density Poly Ethylene

No. : Number

PE : Poly Ethylene

PP : Poly Propylene

PVC : Poly Vinyl Chloride

PVDC : Poly Vinyl Dichloride

Q.C. : Quality Control

S.S : Stainless Steel

SOP : Standard Operating Procedure

STP : Stores Procedure

UDAF : Uni directional air flow

VLAF : Vertical Laminar Air Flow

4.0 REFERENCES:

CQA : Handling of silica gel bags.

STP : Cleaning and Line Clearance of Dispensing area.

5.0 ANNEXURES:

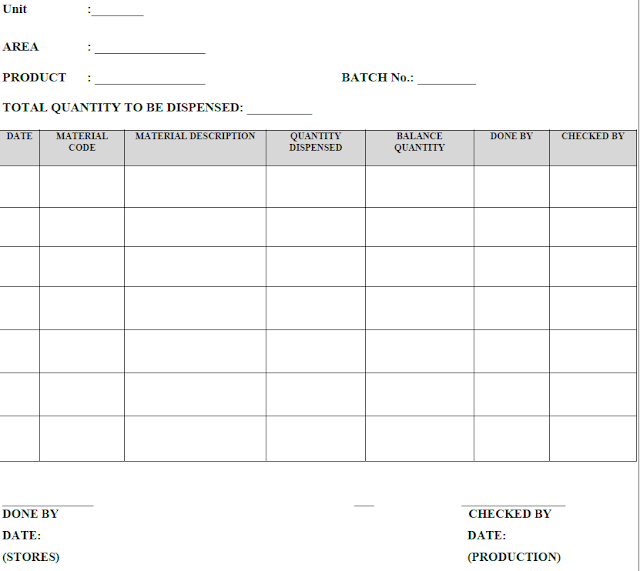

ANNEXURE I

DISPENSING OF PACKAGING MATERIAL IN MULTIPLE DAYS

.webp)

%20Web%20of%20pharma%20.webp)

.webp)