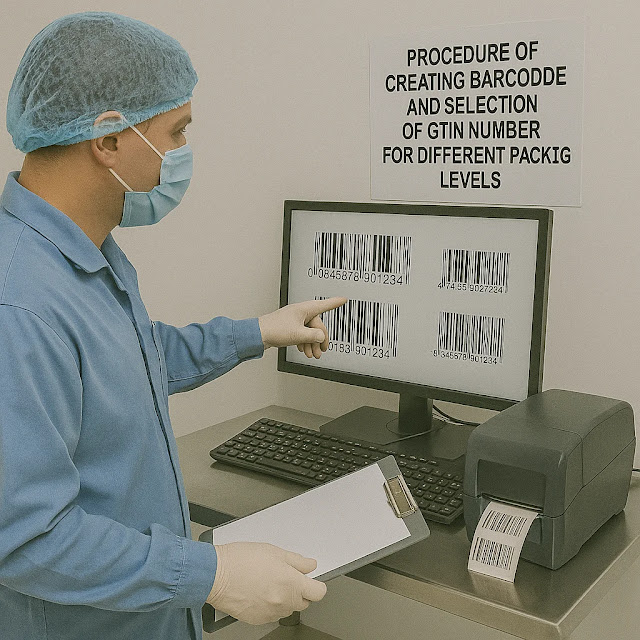

In this post Standard Operating Procedure of Procedure of creating Barcode and selection of GTIN number for different Packing levels in pharmaceuticals is describe.

1.0 OBJECTIVE:

To lay down a procedure of creating Barcode and selection of GTIN number for different packing levels.

2.0 SCOPE:

This procedure is applicable for creating the Barcode and selection of GTIN number for different Packing levels in production department.

3.0 RESPONSIBILITY:

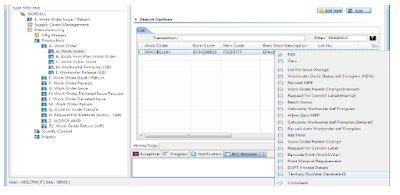

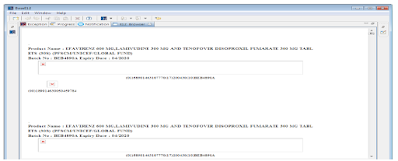

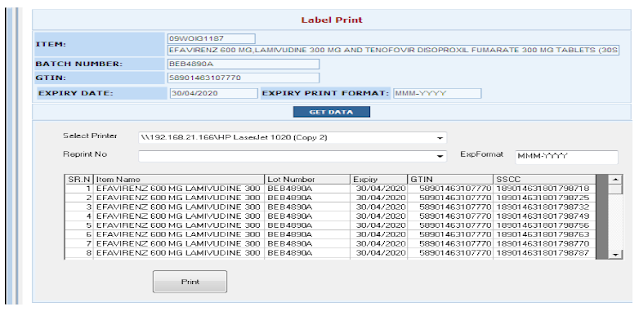

Officer/ Executive- Production: Creating Barcode and printing of Barcode Label. Head–Production/ Designee: SOP compliance.

IPQA: For Specimen approval.

4.0 DEFINITION (S):

GTIN: It stands for Global Trade Item Number and contains 14 digits unique number which used to identify the trade items. GTIN is uniquely assigned to every levels of packaging of product.

Example of GTIN for US market: ………………….

Example of GTIN for other market: ………………..

NDC: It stands for National Drug Code, is a unique 10-digit, 3-segment number. It is a universal product identifier for human drugs in the United States. The 3-segments of the NDC identify the labeler, the product, and the commercial package size. The first set of numbers in the NDC identifies the labeler (manufacturer, re-packager, or distributor). The second set of numbers is the product code, which identifies the specific strength, dosage form (i.e, capsule, tablet, liquid) and formulation of a drug for a specific manufacturer. Finally, the third set is the package code, which identifies package sizes and types. The labeler code is assigned by the FDA, while the product and package code are assigned by the labeler.

Example of NDC: …-…-..

….. : Identify the labeler (manufacturer, re-packager, or distributor).

… : Identify the product Code.

.. : Identify the Package Code.

5.0 PROCEDURE:

5.1 Procedure for selection of GTIN number for US market:

GTIN for US market shall be consisting of 14 Digits as NDC based as follow: Indicator Digit

(Packing Level): 1 Digit

Country Code: 2 Digits

NDC number assigned for the product: 10 Digits Check Digit: 1 Digit

Indicator digit would change depending upon the different packing levels i.e. Primary, Secondary Tertiary and Pallet.

5.1.1 A typical GTIN number would look like ………………… which is of 14 digits where in :

• ……. represent the Indicator Digit for Primary Packing Level.

• …… digits represent the Country Code

• ………….10 digits Stands for NDC number of the product

• ……. represent the check Digit.

5.1.2 The indicator digit would change depending upon the different levels of packing.

There can be multiple packing levels and indicator digit would be in increment pattern as per the packing sequence of product for US markets.

5.1.3 Example discussed below for elaboration by considering the different packing patterns in bottle pack.

Case 1: If labeled bottles are packed in inner shipper and then outer shipper

0 It would be the indicator digit for GTIN on sticker label of bottle pack. GTIN would be 0……………

1 It would be the indicator digit for GTIN of inner shipper. GTIN would be 1…………….

5 It would be the indicator digit for GTIN of outer shipper. GTIN would be 5…………..

6 It would be the indicator digit for GTIN for pallet level. GTIN would be 6………..

Case 2: If labeled bottles are packed in carton then inner shipper and then outer shipper.

0 It would be the indicator digit for GTIN on sticker label of bottle pack. GTIN would be

0……………..

1 It would be the indicator digit for GTIN of carton containing the Bottles. GTIN would be

1……………..

2 It would be the indicator digit for GTIN of inner shipper containing cartons.

GTIN would be 2…………

5 It would be the indicator digit for GTIN of outer shipper containing inner shippers. GTIN

would be 5……………

6 It would be the indicator digit for GTIN for pallet level. GTIN would be 6…………….

5.1.4 Example discussed below for elaboration by considering the different packing patterns in

Blister pack.

Case 1: If blisters are packed in carton and then in outer shipper.

0 It would be the indicator digit for GTIN on Blister pack (If Applicable). GTIN would be 0…………….

1 It would be the indicator digit for GTIN of carton. GTIN would be 1……………..

5 It would be the indicator digit for GTIN of outer shipper. GTIN would be 5……………..

6 It would be the indicator digit for GTIN for pallet level. GTIN would be 6……………

Case 2: If blisters are packed in inner carton and outer carton then in outer shipper.

0 It would be the indicator digit for GTIN on Blister pack (If Applicable). GTIN would be

0………………..

1 It would be the indicator digit for GTIN of inner carton. GTIN would be 1………………….

2 It would be the indicator digit for GTIN of outer carton. GTIN would be 2………………….

5 It would be the indicator digit for GTIN of outer shipper. GTIN would be 5……………….

6 It would be the indicator digit for GTIN for pallet level. GTIN would be 6………………..

5.2 Procedure for selection of GTIN number for other market: GTIN for other market shall be consisting of 14 Digits as follow: Indicator Digit (Packing Level): 1 Digit

.webp)

%20Web%20of%20pharma%20.webp)