In this post Standard Operating Procedure of Cleaning & Operation of Pot Sieve in pharmaceuticals is describe.

1.1 To lay down a procedure for cleaning and Operation of Pot Sieve.

2.0 SCOPE:

2.1 This procedure is applicable for cleaning and Operation of Pot Sieve in production area.

3.0 RESPONSIBILITY:

3.1 Technical associate Production : Cleaning and Operation

3.2 Officer and Executive : Supervision

3.3 Head Production : SOP compliance

4.0 DEFINITION (S):

4.1 NA

5.0 PROCEDURE:

5.1 CLEANING

5.1.1 Affix “TO BE CLEANED” label on the equipment during No activity and affix “UNDER CLEANING” label during cleaning of the equipment as per reference SOP (Status labeling).

5.1.2 Transfer the Pot Sieve to wash area.

5.1.3 Remove the cladding from the Sieve and separate the sieve from the cover.

5.1.4 Clean the sieve by using purified water with a nylon brush.

5.1.5 Clean the cladding by using purified water with Lint free Duster.

5.1.6 Finally rinse the pot sieve with 10 liter of purified water.

5.1.8 Dry the Pot sieve and Assemble the dry part of the Pot sieve.

5.1.9 Inform the QA to collect swab/rinse water sample if required.

Frequency: After every filtration.

5.2 OPERATION:

5.2.1 Ensure that the equipment is cleaned and ready for use.

5.2.2 Visually check the sieve integrity after and before use of the pot sieve.

5.2.3 Place the pot sieve on the mouth of the container or tank.

5.2.4 Filter the solution through the upper opening of the pot sieve.

5.2.5 After completion of process place the pot sieve in poly bag.

5.2.6 Affix “TO BE CLEANED” label on the equipment and transfer the Pot sieve to the respective wash area as per reference SOP (Status labeling).

5.2.7 Affix “UNDER CLEANING” label during cleaning of the equipment as per reference SOP (Status labeling).

6.0 ABBREVIATION (S):

6.1 Q.A. : Quality Assurance.

6.2 SOP : Standard Operating Procedure.

7.0 RERERENCE (S):

7.1 NA

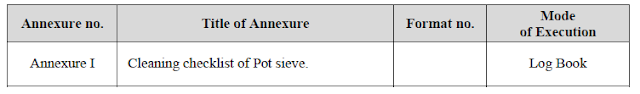

8.0 ANNEXURE (S):

9.0 DISTRIBUTION:

9.1 Master Copy : Quality Assurance

9.2 Controlled copy (S) : Production department (01), Quality Assurance (01)

9.3 Reference copy (S) : Production department (01)

10.0 REVISION HISTORY:

.webp)

%20Web%20of%20pharma%20.webp)