In this post Standard Operating Procedure of Cleaning & Operation of Condot Printer in pharmaceuticals is describe.

1.0 OBJECTIVE:

1.1 To lay down a procedure for Cleaning and Operation of Condot Printer.

2.0 SCOPE:

2.1 This procedure is applicable to Cleaning and Operation of Condot Printer in Tablet Production department.

3.0 RESPONSIBILITY:

3.1 Technical Associate: Cleaning and Operation of Condot Printer

3.2 Officer/ Executive Production/IPQA: Supervision of cleaning and operation

3.3 Head Production: SOP Compliance.

3.4 IPQA: Line clearance and online process confirmation.

4.0 DEFINITION(S):

4.1 NA

5.0 PROCEDURE:

5.1 Cleaning:

5.1.1 Carry out the following procedure at batch or product changeover.

5.1.2 Switch ‘OFF’ the mains of the machine.

5.1.3 Replace the EQUIPMENT STATUS label with UNDER CLEANING status label with date and signature of production officer.

5.1.4 Remove all over printed material and destroy them after reconciliation as per respective BPR.

5.1.5 Remove the unprinted material from the machine.

5.1.6 Remove the packing material from line.

5.1.7 Clean the sensor with dry lint free cloth.

5.1.8 Clean the conveyor belt with wet cloth followed by lint free cloth.

5.1.9 Cleaning For Printed Head

5.1.9.1 Remove the ink cartridge from the printing unit.

5.1.9.2 Clean the head of ink cartridge with tissue paper.

5.1.9.3 Store the ink cartridge into the poly bag.

5.1.10 FREQUENCY: At the end of process.

5.2 Machine Setup And Operation :

5.2.1 Ensure that packing machine is cleaned.

5.2.2 Start the machine by using ‘ON’/‘OFF’ switch and receive the carton from conveyor of packing machine and adjust the speed through provided knob and deliver the carton to Condot printer.

5.2.3 Feed one by one carton and maintain the distance between the two consecutive cartons.

5.2.4 Setup Of Condot Printer:

5.2.4.1 Insert the data card into the card reader and attach and attach the data card to computer.

5.2.5 Feed the coding programmed as per below instruction(message editing):

5.2.5.1 Open the OBJ INK draw program from desktop.

5.2.5.2 Click on new option of file option for new message editing.

Select the HP51645A head type→select TCU option → select 12.7mm in Head engine type→Click on ‘ADD’ followed by ‘OK’ →a area for new message will be appeared on screen.

5.2.5.3 Select the ABCD option from the icon →make a text line area.and type the message line by line in the text column giving on the top of the icon by pressing the enter key.Save the message in the TCU folder situated in ‘INK DRAW’ folder which is situated in program file of c/: disk.

5.2.5.4 Move the message to to the data card from system by using the yellow coloured folder icon situated at top of icon.

5.2.5.5 Select F: drive and type the message name such as TCU-1(1 TO 10 ONLY)-click on save.

5.2.5.6 Cut off the link of the data cable from the computer system and remove the data card.

5.2.5.7 Insert the data card into the setup box and select the message ‘NO’ from the message selecting knob situated on lower side of machine and then switch ‘ON’ the machine and press ‘START’ button situated on setup box.

5.2.5.8 Turn knob toward the ‘ON’ button then press ‘RUN’ and after pressing the machine Will start.

5.2.5.9 After completion of operation switch ‘OFF’ electrical supply.

5.2.5.10 NOTE: In case of chocking of printer use special function key to remove the dried ink from printing head.

6.0 ABBREVIATION (S):

6.1 SOP: Standard Operating Procedure.

7.0 REFERENCE(S):

7.1 SOP: Status labeling

8.0 ANNEXURE (S):

8.1 NA

9.0 DISTRIBUTION:

9.1 Master Copy: Quality Assurance

9.2 Controlled Copy (s): Production department (02), Quality Assurance (01)

9.3 Reference Copy (s): Production department (01)

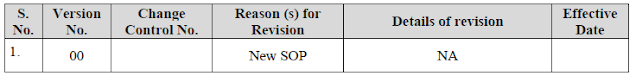

10.0 REVISION HISTORY:

.webp)

%20Web%20of%20pharma%20.webp)